In the realm of structural engineering, a novel technique for strengthening reinforced concrete (RC) columns has emerged, promising enhanced performance and safety, particularly under eccentric loading conditions. This innovative method, known as the corner strip-wrap technique, employs fiber-reinforced polymer (FRP) composites to fortify columns, offering a compelling alternative to traditional wrapping methods. The research, led by Alireza Saljoughian from the Department of Civil Engineering at Isfahan University of Technology (IUT), Iran, and published in the journal ‘مهندسی عمران شریف’ (translated as ‘Sharif Civil Engineering’), presents a significant advancement with potential implications for the energy sector and beyond.

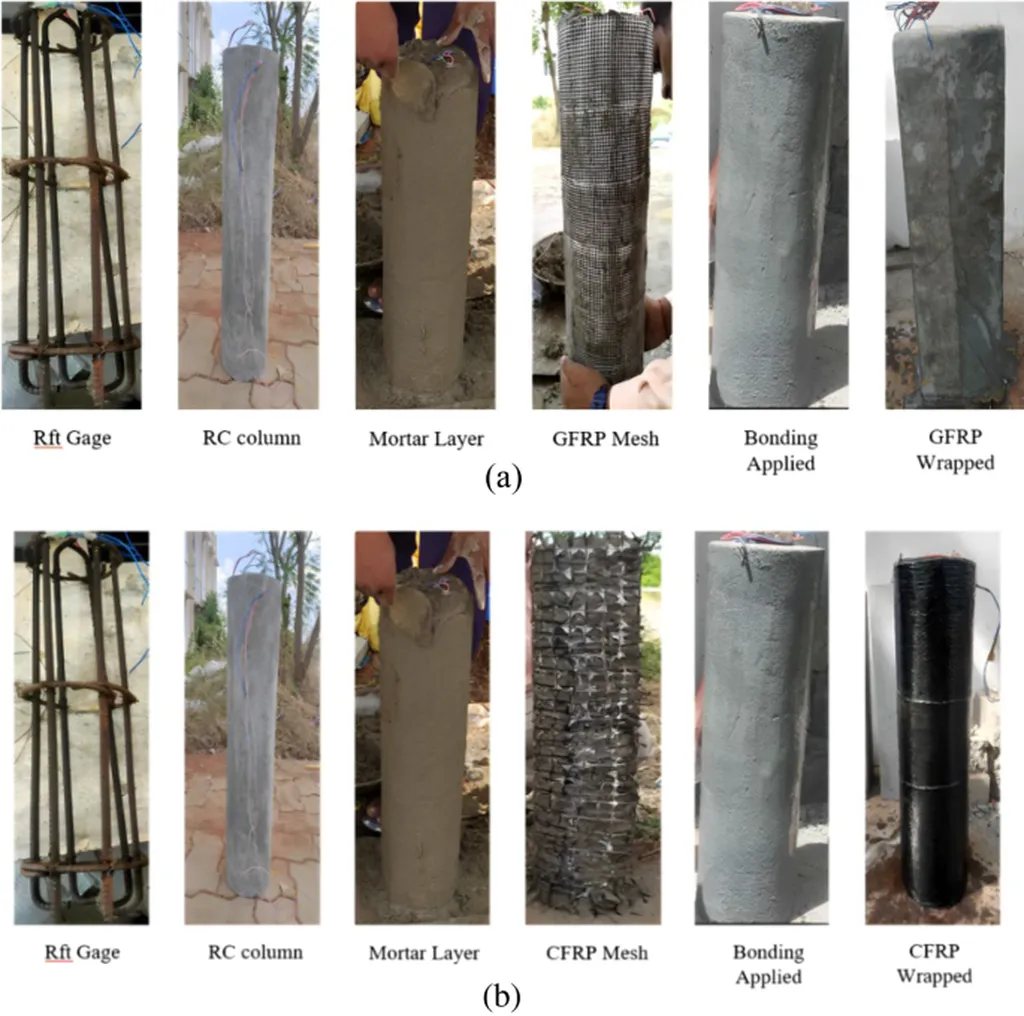

The study focused on the axial and flexural behavior of RC columns retrofitted with FRP composites using the corner strip-wrap technique. To evaluate its effectiveness, Saljoughian and his team tested ten square RC columns under varying levels of eccentricity, comparing the novel technique with conventional wrapping methods. The results were striking. Columns confined using the corner strip-wrap technique demonstrated a remarkable increase in load-carrying capacity and ductility, particularly under eccentric loading conditions.

“Columns confined with the corner strip-wrap technique exhibited a 15% increase in load-carrying capacity compared to those confined through the conventional wrapping technique when subjected to zero eccentricity,” Saljoughian explained. “Moreover, the ductility enhancements were even more pronounced, with increases of 607% and 330% compared to unconfined columns under zero and 60 mm eccentricities, respectively.”

The implications of this research are far-reaching, particularly for the energy sector where structural integrity is paramount. Oil and gas facilities, power plants, and other critical infrastructure often require robust and resilient structural components to withstand various loading conditions. The corner strip-wrap technique offers a promising solution for retrofitting existing structures and enhancing their performance, thereby extending their service life and improving safety.

One of the key advantages of the corner strip-wrap technique is its ability to provide superior performance under eccentric loading, a common scenario in real-world applications. Eccentric loads can significantly reduce the load-carrying capacity and ductility of confined RC columns, but the corner strip-wrap technique mitigates these effects more effectively than traditional methods.

The study also highlighted the conservative nature of code-based estimates compared to experimental measurements, suggesting that the corner strip-wrap technique may offer even greater benefits than currently anticipated. This finding underscores the importance of continued research and innovation in the field of structural engineering.

As the energy sector continues to evolve, the demand for advanced materials and techniques to enhance structural performance will only grow. The corner strip-wrap technique represents a significant step forward in this regard, offering a versatile and effective solution for strengthening RC columns. With further research and development, this innovative approach could become a standard practice in the industry, contributing to safer and more resilient infrastructure.

In conclusion, the research led by Alireza Saljoughian and published in ‘مهندسی عمران شریف’ (Sharif Civil Engineering) presents a compelling case for the adoption of the corner strip-wrap technique in the retrofitting of reinforced concrete columns. Its potential to enhance load-carrying capacity and ductility, particularly under eccentric loading conditions, makes it a valuable tool for engineers and practitioners in the energy sector and beyond. As the industry continues to seek innovative solutions to complex structural challenges, this technique offers a promising path forward.