In the quest to optimize energy consumption in industrial processes, a recent study published in *Zhileng xuebao* (translated as *Building Science Journal*) has shed light on the intricate relationship between pre-cooling air velocities and energy efficiency. Led by Liu Bin, the research delves into the theoretical and experimental analyses of how varying air velocities impact both the energy consumption of air fans and the overall pre-cooling effects. This study could have significant implications for the energy sector, particularly in industries where cooling processes are critical.

Liu Bin, whose affiliation details are not specified, explains that the research was motivated by the need to balance energy consumption with effective cooling. “By understanding how different air velocities affect the cooling process, we can optimize systems to reduce energy use without compromising performance,” Liu Bin states. This balance is crucial for industries aiming to cut operational costs and reduce their carbon footprint.

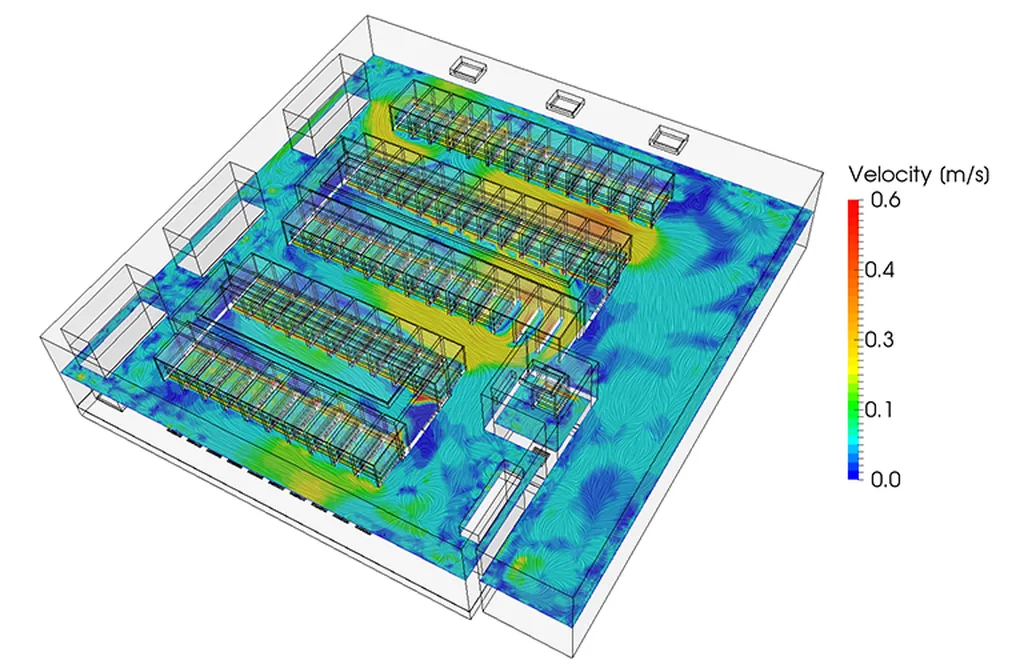

The study’s findings suggest that there is an optimal range of air velocities that minimizes energy consumption while maximizing cooling efficiency. This is particularly relevant for sectors such as data centers, food processing, and chemical manufacturing, where cooling systems are integral to operations. By fine-tuning air velocities, companies can achieve substantial energy savings, which translates to lower operational costs and a more sustainable approach to industrial processes.

One of the key insights from the research is the identification of the point at which increasing air velocity no longer yields significant cooling benefits but instead leads to increased energy consumption. This threshold is critical for engineers and facility managers to consider when designing and operating cooling systems. “Our research provides a data-driven approach to making these decisions, ensuring that cooling systems are both efficient and effective,” Liu Bin notes.

The implications of this research extend beyond immediate energy savings. As industries strive to meet increasingly stringent environmental regulations, the ability to optimize cooling processes becomes a strategic advantage. Companies that adopt these findings can position themselves as leaders in sustainability, potentially attracting environmentally conscious clients and investors.

Moreover, the study’s focus on both theoretical and experimental analyses ensures that the findings are not only academically robust but also practically applicable. This dual approach provides a comprehensive understanding of the dynamics involved, making it easier for industry professionals to implement the recommendations.

As the energy sector continues to evolve, research like Liu Bin’s plays a pivotal role in shaping future developments. By providing a clear, evidence-based framework for optimizing cooling processes, this study offers a roadmap for industries to enhance their energy efficiency and sustainability efforts. The publication in *Zhileng xuebao* further underscores the significance of this work, as it reaches a global audience of professionals and academics in the field.

In conclusion, Liu Bin’s research represents a significant step forward in the quest for energy-efficient cooling solutions. By offering actionable insights into the relationship between air velocities and energy consumption, it equips industries with the tools they need to make informed decisions. As the world moves towards a more sustainable future, such innovations will be crucial in driving progress and achieving environmental goals.