In the ever-evolving world of construction and civil engineering, a groundbreaking study has emerged that could significantly impact how we approach seismic-resistant structures, particularly in the energy sector. The research, led by Mohamad Reza Shokrzadeh from the Department of Civil Engineering at the Science and Research Branch of Islamic Azad University in Tehran, Iran, delves into the seismic behavior and modification of mechanical bar splices, a critical component in reinforced concrete (RC) structures.

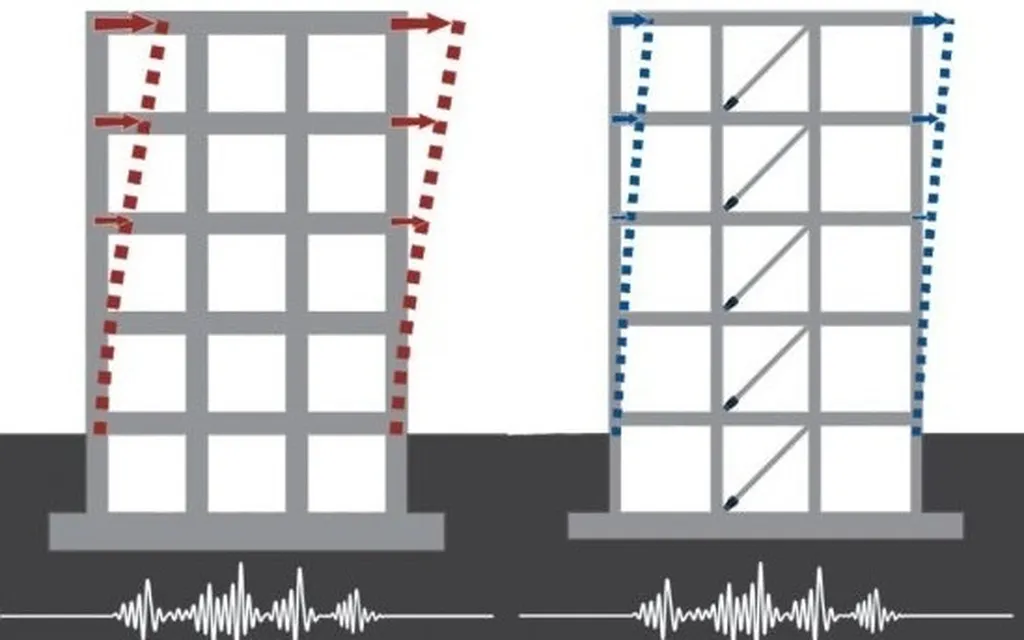

The problem of overcrowding at the junction of reinforcing bars is particularly significant in seismic detailing. Traditional splicing methods often fall short, and that’s where mechanical couplers come into play. These rigid components join reinforcement bars together, offering a solution that eliminates the disadvantages of conventional splicing methods. However, the failure mechanism of threaded splices under tensile and cyclic loads has not been thoroughly investigated until now.

Shokrzadeh’s study introduces two innovative patch types by modifying the threaded splice method and combining it with rotary friction welding. The goal? To enhance the coupler’s failure area and make it suitable for use in the plastic hinge areas of ductile members in seismic zones. “The splice area in the suggested method is large,” Shokrzadeh explains. “We used two techniques to increase the splice area: cold rolling and rotating friction welding.”

The research involved testing 96 samples, including threaded couplers (TC), oversized-threaded couplers (OTC), rotary friction welding splices with threaded couplers (RFWTC), and non-spliced (NS) reference specimens. These were subjected to uniaxial tensile and cyclic tests, both with and without concrete. The evaluations covered sensitivity to bar diameter, bar strength, ductility, energy absorption, and failure mode performance.

The results were promising. The RFWTC and OTC exhibited superior performance in terms of strength, ductility, energy absorption, and failure mode, making them ideal for high seismic zones. The TC, on the other hand, proved suitable for low to medium seismic activity areas. “The anticipated model is sufficient for estimating the threaded couplers’ ultimate tensile strength,” Shokrzadeh notes.

So, what does this mean for the future of construction, particularly in the energy sector? The implications are substantial. As we strive to build more resilient infrastructure, especially in seismic zones, these innovative splicing methods could become a game-changer. They offer enhanced performance and reliability, which are crucial for the safety and longevity of structures.

Moreover, the energy sector, which often operates in challenging environments, stands to benefit significantly from these advancements. From power plants to renewable energy installations, the ability to ensure structural integrity in seismic zones is paramount. This research could pave the way for more robust and reliable construction practices, ultimately leading to safer and more sustainable energy infrastructure.

Published in the journal ‘مهندسی عمران شریف’, which translates to ‘Sharif Journal of Civil Engineering’, this study is a testament to the ongoing innovation in the field. As we look to the future, it’s clear that such advancements will play a pivotal role in shaping the landscape of civil engineering and construction, ensuring that our structures are not only stronger but also more resilient in the face of natural challenges.