In the relentless pursuit of materials that can withstand the harshest environments, researchers have turned to an age-old technique to breathe new life into a modern alloy. Monel 400, a nickel-copper alloy renowned for its corrosion resistance, has long been a staple in industries like maritime, oil and gas, and chemical processing. However, its relatively low wear resistance has been a persistent challenge. Now, a team of researchers led by Christian Pacheco from the Universidad de Santiago de Chile has demonstrated a promising solution: boriding.

Boriding, a thermochemical treatment process, has been used for decades to enhance the surface properties of metals. The process involves diffusing boron atoms into the surface of the metal, forming a hard, wear-resistant layer. In their study published in ‘Materials Research’ (translated as ‘Pesquisa em Materiais’), Pacheco and his team applied this technique to Monel 400, using a boriding powder containing 90% B4C and 10% KBF4 at a temperature of 900 °C for 4 hours.

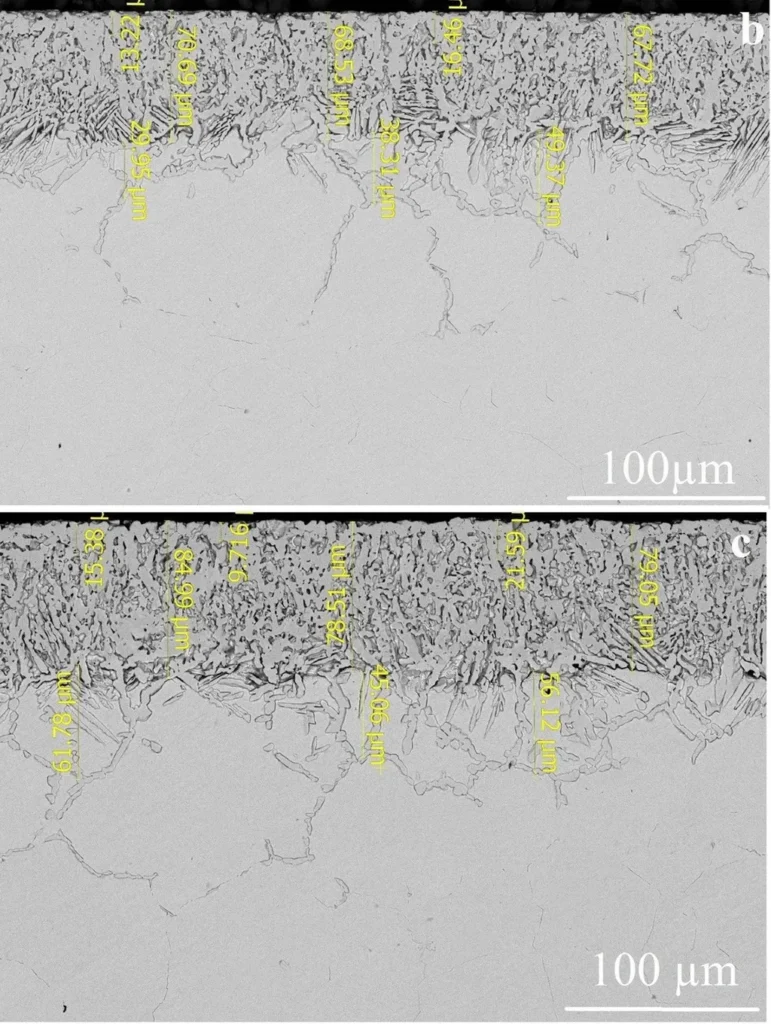

The results were impressive. The borided layer, predominantly composed of nickel borides (Ni2B, Ni3B, and Ni4B3), achieved a hardness of up to 1600 HV0,01, a significant improvement over the untreated alloy. “The wear resistance of the borided Monel 400 was markedly enhanced,” Pacheco explained, “making it a promising candidate for applications in abrasive environments.”

The team evaluated the wear performance of the treated and untreated samples using pin-on-disk tests, analyzing wear rates, removed volume, and surface roughness using profilometry, confocal microscopy, and scanning electron microscopy (SEM). The borided layer demonstrated strong adhesion to the substrate, a critical factor for the longevity of the treated material.

The implications of this research are significant for the energy sector, particularly in applications such as pumps, valves, and other components exposed to abrasive environments. “This study highlights the potential of boriding as an effective treatment to extend the service life of Monel 400,” Pacheco noted. By enhancing the wear resistance of this already corrosion-resistant alloy, boriding could lead to more durable, long-lasting components, reducing maintenance costs and downtime.

The research also opens up new avenues for exploring other thermochemical treatments and their potential to enhance the properties of various alloys. As Pacheco and his team continue to investigate these possibilities, the future of materials science looks increasingly promising. “We are excited about the potential of this technique,” Pacheco said, “and we look forward to exploring its applications further.”

In the ever-evolving landscape of materials science, this study serves as a reminder of the power of innovation and the potential of age-old techniques to address modern challenges. As the energy sector continues to demand more from its materials, research like this paves the way for a future where durability and performance go hand in hand.