In the quest for more efficient energy solutions, researchers have turned to an unlikely ally: artificial intelligence. A recent study published in the journal *Science, Technology and Advanced Materials: Methods* (translated from Japanese) demonstrates how machine learning can significantly enhance the performance of thermoelectric materials, potentially revolutionizing the energy sector.

Thermoelectric materials, which convert heat into electricity, hold promise for waste heat recovery in industrial processes and power generation. However, optimizing their performance has been a daunting task due to the complex interplay of various processing conditions. Enter Florent Pawula, a researcher at the National Institute for Materials Science (NIMS) in Japan, and his team, who have harnessed the power of active learning and Bayesian optimization to navigate this intricate landscape.

Pawula and his colleagues focused on germanium telluride (GeTe), a mid-temperature thermoelectric material with untapped potential. “The challenge with GeTe is that its performance is highly sensitive to processing conditions,” Pawula explains. “We’re talking about an eleven-dimensional process space, which is a massive haystack to search through.”

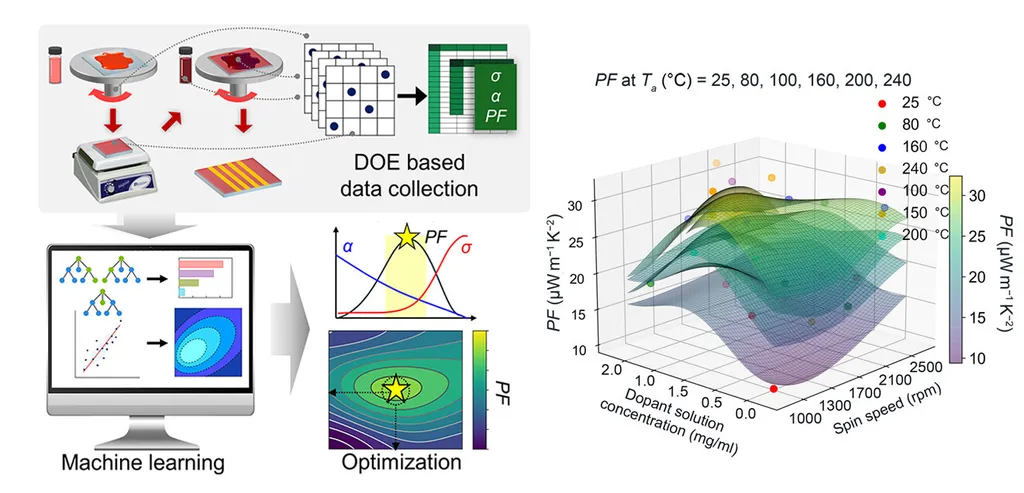

Traditional methods of optimizing GeTe’s performance involve time-consuming and labor-intensive trial-and-error processes. Pawula’s team took a different approach, combining active learning with Bayesian optimization (ALBO) to efficiently explore this vast parameter space. Starting with just five random experiments, the ALBO algorithm iteratively proposed new processing recipes, synthesizing and characterizing each batch to retrain the surrogate model.

The results were impressive. After only 24 experiments—an astonishingly small number compared to the exhaustive search—the team achieved a 25% improvement in GeTe’s figure-of-merit, a key indicator of thermoelectric performance. This gain is comparable to multi-day three-step protocols, highlighting the efficiency of the ALBO approach.

“ALBO provides a time- and energy-efficient path to process optimization,” Pawula says. “It not only helps us find the best processing conditions but also exposes the key levers that govern transport in GeTe.”

The implications for the energy sector are significant. By enabling more efficient thermoelectric materials, this research could pave the way for better waste heat recovery systems, enhancing energy efficiency in industrial processes and power generation. Moreover, the ALBO strategy is readily transferable to other materials where processing, rather than chemistry, limits performance.

As the world seeks to transition to a more sustainable energy future, innovations like Pawula’s ALBO approach offer a glimpse into how artificial intelligence can drive progress. By making the most of existing materials and processes, we can unlock new possibilities for energy efficiency and sustainability.

In the words of Pawula, “This is just the beginning. The potential for AI-driven materials design is vast, and we’re excited to see where it takes us.”