In a groundbreaking study published in the *Magazine of Civil Engineering* (translated from Russian as *Journal of Civil Engineering*), researchers have unveiled a novel methodology for calculating the bearing capacity of lightweight steel concrete enclosure wall panels (LSCS). This research, led by Rybakov Vladimir from Peter the Great St. Petersburg Polytechnic University, promises to revolutionize the construction industry, particularly in the energy sector, by enhancing the efficiency and safety of building envelopes.

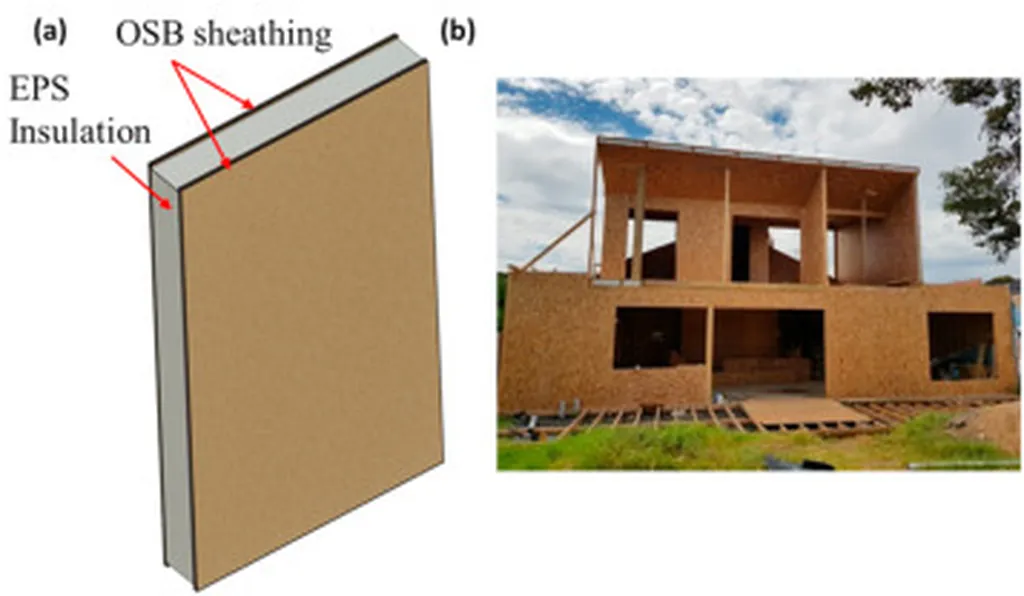

The study focuses on LSCS panels, which consist of light gauge steel profiles filled with foam lightweight cellular concrete. These panels are increasingly popular due to their lightweight nature, ease of installation, and excellent insulation properties. However, their fastenings have often posed a challenge in terms of bearing capacity and structural integrity.

Rybakov and his team conducted an experimental study to understand the behavior of LSCS panels under distributed loads, simulating wind pressure. They discovered that the density of the foam concrete used in the panels was 370 kg/m³, a crucial factor in determining the panel’s performance. The researchers developed a methodology for calculating the bearing capacity of LSCS panel-to-slab fastenings, which was validated through experimental data.

“The analytically calculated destructive load was 28.25 kN, which is only 9.3% less than the experimentally obtained destructive load of 30.9 kN,” Rybakov explained. This close correlation between theoretical and experimental results underscores the robustness of the proposed methodology.

One of the key findings of the study is that the loss of load-bearing capacity in the panel occurs due to the bearing of the steel sheet of the web of the light gauge steel profile. Additionally, the rigidity of the LSCS panel fastenings varies significantly under different load conditions. Initially, the behavior of the panel corresponds to a fixed-support calculation scheme. However, as the load increases, the fasteners transition to a finite stiffness support and eventually turn into a plastic hinge.

“This research provides a comprehensive understanding of the behavior of LSCS panels under various loading conditions,” Rybakov noted. “It offers a practical approach for engineers to design and implement these panels in real-world applications.”

The implications of this research are far-reaching, particularly for the energy sector. Lightweight steel concrete enclosure wall panels are increasingly being used in the construction of energy-efficient buildings. The enhanced understanding of their behavior and the proposed methodology for calculating their bearing capacity will enable engineers to design more efficient and safer building envelopes. This, in turn, can lead to significant energy savings and reduced environmental impact.

As the construction industry continues to evolve, the insights gained from this study will undoubtedly shape future developments in the field. By providing a reliable methodology for calculating the bearing capacity of LSCS panels, Rybakov and his team have laid the groundwork for more innovative and sustainable construction practices.

In the words of Rybakov, “This research is a step towards a more efficient and safer future for the construction industry.” With the publication of this study in the *Magazine of Civil Engineering*, the industry is one step closer to achieving that goal.