In the ever-evolving world of construction and civil engineering, researchers are continually seeking innovative methods to enhance the stability and efficiency of underground structures. A recent study published in the journal *Discover Materials* (which translates to “Materials Discovery”) has introduced a novel approach to evaluating the performance of circular tunnels surrounded by tire-derived aggregates (TDA). This research, led by Md. Foisal Haque from the Department of Civil Engineering at the International University of Business Agriculture and Technology, offers a simplified yet accurate method for assessing the strain and deflection of tunnels, with significant implications for the energy sector.

The study proposes treating circular tunnels as simplified beam elements with fixed ends, allowing for a linear elastic analysis under gravity loading. This approach provides an unconditional stable explicit solution, making it easier to evaluate the structural responses of tunnels. “The idea was to simplify the complex three-dimensional analysis into a more manageable two-noded beam element model,” explains Haque. “This not only reduces computational complexity but also maintains a high level of accuracy, as evidenced by our validation with previous three-dimensional numerical analyses.”

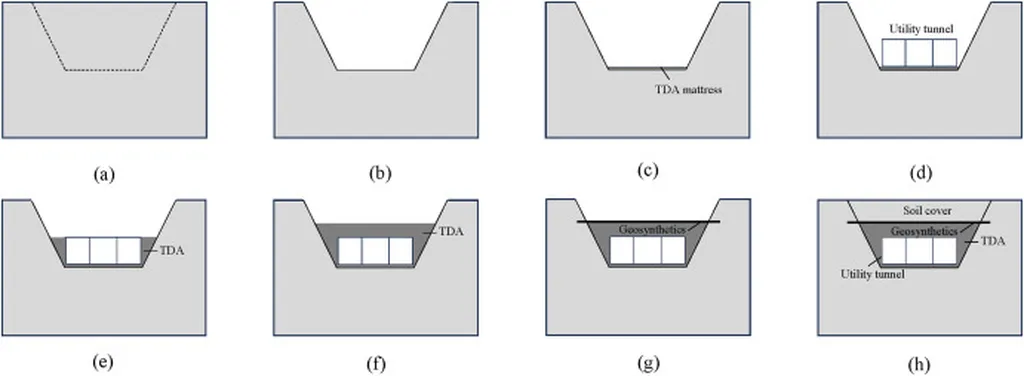

The research found that the strain and deflection of the tunnel increase with the relative tunnel covers due to the added self-weights of soil and TDA. Conversely, increasing the tunnel thickness reduces these responses by enhancing the beam’s stiffness. One of the most compelling findings is that the use of TDA can decrease the tunnel responses by up to 24.4%, highlighting the potential of recycled materials in improving structural performance.

For the energy sector, these findings are particularly relevant. Underground tunnels are crucial for various energy infrastructure projects, including the transportation of oil, gas, and other resources. The ability to accurately predict and manage strain and deflection in these structures can lead to more robust and cost-effective designs. “By incorporating TDA, we can not only enhance the structural integrity of tunnels but also contribute to sustainable practices by repurposing waste materials,” Haque adds.

The commercial impact of this research is substantial. Energy companies can benefit from more efficient and safer tunnel designs, reducing maintenance costs and minimizing the risk of structural failures. Additionally, the use of TDA aligns with the growing emphasis on sustainability and circular economy principles, making it an attractive option for environmentally conscious projects.

As the construction industry continues to evolve, the integration of advanced analytical techniques and sustainable materials will play a pivotal role in shaping the future of infrastructure development. Haque’s research offers a promising step in this direction, providing a practical and accurate method for evaluating tunnel performance while promoting the use of recycled materials. With further advancements, this approach could become a standard practice in the design and construction of underground structures, benefiting both the energy sector and the environment.