In the ever-evolving world of construction materials, a groundbreaking study led by Xiaofei Zhang from Southeast University’s Key Laboratory of C & PC Structures has shed new light on the potential of basalt fiber-reinforced polymer (BFRP) textiles in enhancing the flexural performance of thin concrete plates. Published in the journal *Case Studies in Construction Materials* (translated as “典型建筑材料研究”), this research could have significant implications for the energy sector, particularly in the design and retrofitting of structures.

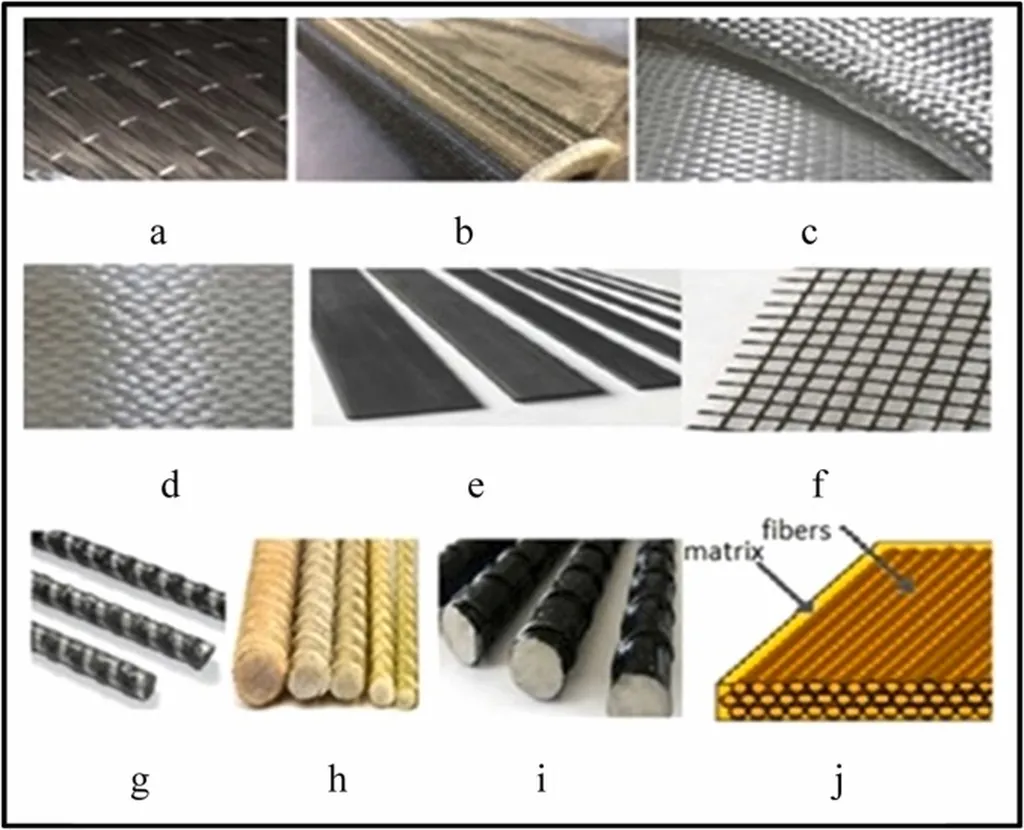

The study delves into the intricate world of textile-reinforced concrete (TRC), a composite material that has garnered attention for its high strength, light weight, and corrosion resistance. “Textile-reinforced concrete offers a promising alternative for constructing thin-walled elements and retrofitting damaged structures,” Zhang explains. “Our research focuses on understanding how the geometric characteristics of BFRP textiles influence the flexural behavior of these concrete plates.”

The findings are compelling. By increasing the number of textile layers from one to three, the researchers observed an impressive 85.9% improvement in ultimate bending stress and an 84.4% enhancement in toughness. This suggests that the number of layers plays a crucial role in stress distribution and crack control, which could lead to more robust and durable structures.

However, not all textile configurations are created equal. The study found that plates reinforced with straight yarns outperformed those with twisted yarns by 21.5% in ultimate bending stress. “The twisting of yarns adversely affects the axial load-bearing capacity of the textile,” Zhang notes. This insight could guide manufacturers in optimizing the design of BFRP textiles for specific applications.

The research also highlighted the importance of transverse yarn spacing. Increasing this spacing weakened the anchorage effect, crack-bridging capacity, and stress uniformity of the textile, resulting in decreases of up to 23.4% in ultimate bending stress and 76.2% in bending toughness. These findings underscore the need for careful consideration of textile geometry in the design of TRC elements.

Beyond experimental observations, the study developed a flexural capacity prediction model based on classical theory, incorporating transverse yarn spacing. Additionally, a stiffness-based model was used to estimate ultimate deflections, excluding concrete tensile contribution. These models provide valuable tools for engineers and designers to predict the bending performance of BFRP textile-reinforced concrete elements.

The implications for the energy sector are significant. As the demand for sustainable and efficient energy infrastructure grows, the need for innovative construction materials becomes ever more pressing. TRC, with its high strength-to-weight ratio and corrosion resistance, offers a promising solution for constructing and retrofitting energy-related structures, such as wind turbine towers, solar panel supports, and offshore platforms.

“This research provides a basis for optimizing textile geometry and predicting the bending performance of BFRP-reinforced concrete elements,” Zhang concludes. As the construction industry continues to evolve, the insights gained from this study could pave the way for more efficient, durable, and sustainable structures in the energy sector and beyond.