In the quest to enhance the properties of NiTi alloys, a team of researchers led by YU Fei from Lanzhou University of Information Science and Technology and XIE Dong from Southwest Jiaotong University has delved into the effects of thermal oxidation surface modification. Their findings, published in *Cailiao Baohu* (which translates to *Materials Protection*), offer valuable insights that could potentially reshape the energy sector’s approach to material science.

NiTi alloys, known for their superelasticity and shape memory effects, are already widely used in various industries, including medical devices and aerospace. However, their application in the energy sector has been somewhat limited due to concerns about their durability and performance under extreme conditions. The research team aimed to address these issues by investigating the impact of thermal oxidation on the properties of NiTi alloys.

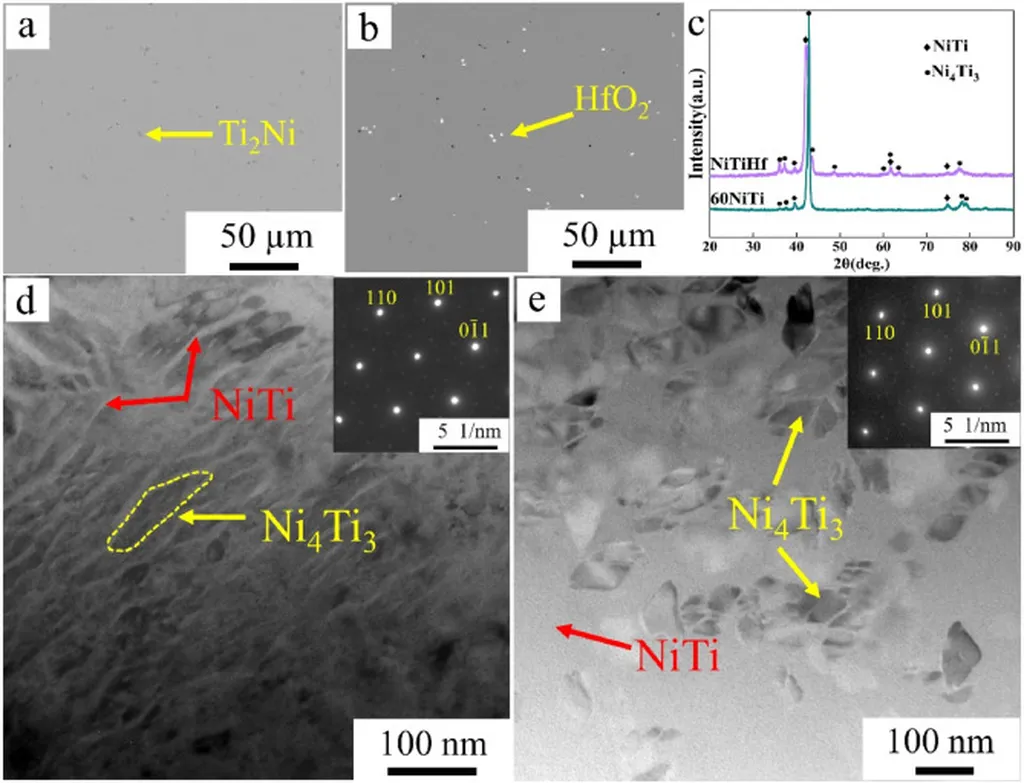

The study involved subjecting NiTi alloys to thermal oxidation at different temperatures ranging from 300 to 700 degrees Celsius. The researchers then analyzed the resulting oxide films, focusing on their morphology, composition, phase structure, phase transformation temperatures, and mechanical properties. “We found that at lower temperatures, the oxide layer formed was very thin and did not significantly alter the alloy’s properties,” explained YU Fei. “However, as the temperature increased, the oxide layer became denser and more pronounced.”

At 600 degrees Celsius, a dense rutile-TiO2 film formed on the surface of the NiTi alloy. However, this film was prone to cracking and peeling after tensile deformation, indicating poor film-substrate adhesion. This discovery was crucial as it highlighted the limitations of high-temperature thermal oxidation in enhancing the alloy’s properties.

The researchers also conducted tensile tests and water bath heating to investigate the influence of thermal oxidation on the superelasticity and shape memory effect of the NiTi alloys. They found that when the thermal oxidation temperature exceeded 400 degrees Celsius, the reverse phase transformation of the NiTi alloy during unloading could not be completed, leading to a degradation of its superelastic properties. However, after water bath heating, the martensitic reverse phase transformation was completed, indicating that high-temperature oxidation did not affect the shape memory effect of the NiTi substrate.

These findings provide important theoretical and experimental references for studying the film-substrate adhesion and coordination properties of thermally oxidized NiTi alloys. The research could pave the way for developing more durable and efficient NiTi alloys for use in the energy sector, particularly in applications that require materials to withstand extreme temperatures and pressures.

As the energy sector continues to evolve, the demand for advanced materials that can perform under harsh conditions is on the rise. This research offers a promising avenue for enhancing the properties of NiTi alloys, potentially opening up new possibilities for their use in energy generation, storage, and transmission. “Our findings could have significant implications for the energy sector,” said XIE Dong. “By understanding the effects of thermal oxidation on NiTi alloys, we can develop materials that are more resilient and better suited to the demands of modern energy systems.”

In conclusion, the research conducted by YU Fei, XIE Dong, and their team offers valuable insights into the thermal oxidation of NiTi alloys. Their findings could shape future developments in material science, particularly in the energy sector, where the demand for advanced materials is ever-growing. As the world transitions towards more sustainable and efficient energy systems, the need for innovative materials that can withstand extreme conditions will only increase. This research is a step towards meeting that need.