In a breakthrough that could revolutionize the coatings industry, researchers have developed a novel type of epoxy-based vitrimer that possesses self-healing capabilities. This innovation, led by Angela Marotta from the Department of Chemical, Materials, and Production Engineering at the University of Naples Federico II, promises to extend the service life of coatings while maintaining their protective performance. The study, published in the journal *Macromolecular Materials and Engineering* (which translates to *Macromolecular Materials and Engineering* in English), opens up new avenues for large-scale applications, particularly in the energy sector.

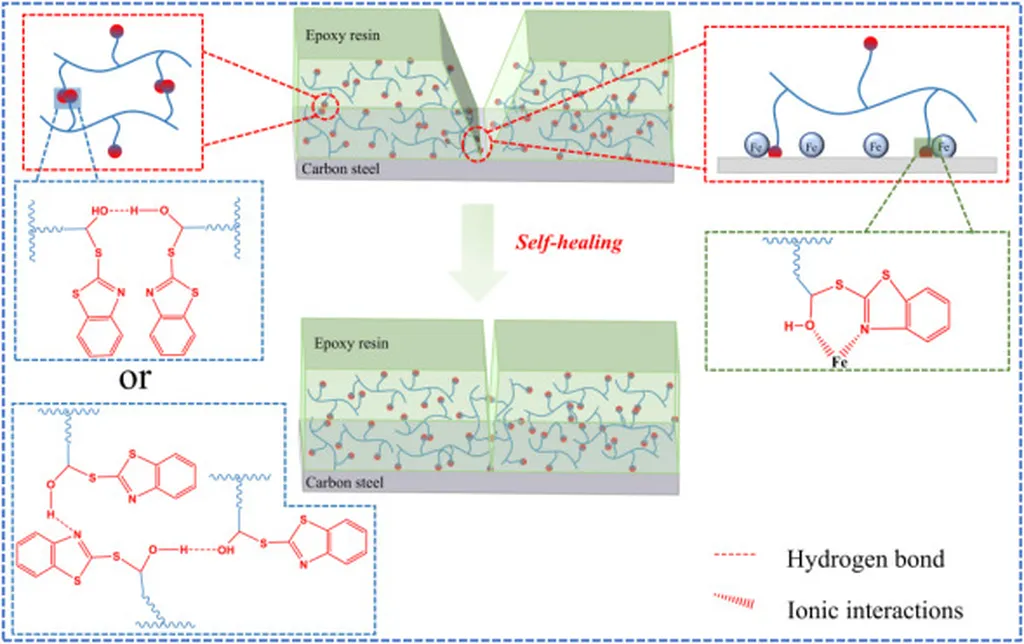

The research focuses on creating epoxy-based vitrimers, a class of polymers that can reversibly exchange bonds under certain conditions. These materials are crosslinked using ethylene glycol diglycidyl ether (EG) and methyl nadic anhydride (MNA), with 1-methylimidazole (1-MI) acting as an initiator. The key to their self-healing ability lies in the transesterification-based bond exchange reactions, which are triggered by heat. This process allows the material to “heal” itself by reforming bonds that have been broken due to wear and tear.

One of the most significant findings of the study is the role of the transesterification catalyst, triazobicyclodecene (TBD), in accelerating the relaxation process. “The relaxation process can be accelerated by both TBD and epoxy excess,” Marotta explains. This means that the material can be tailored to respond more quickly to damage, enhancing its self-healing properties.

The practical implications of this research are substantial. The low viscosity of the epoxy-based formulations allows for easy application to substrates using standard deposition techniques, without the need for solvents or high temperatures. This not only simplifies the application process but also makes it more environmentally friendly. The self-healing ability of these coatings can significantly extend the service life of protected surfaces, reducing maintenance costs and downtime.

In the energy sector, where infrastructure is often exposed to harsh environmental conditions, self-healing coatings could be a game-changer. Pipelines, wind turbines, and other critical assets could benefit from coatings that can automatically repair minor damages, enhancing their durability and reliability. This could lead to substantial cost savings and improved safety standards.

The research also highlights the potential for large-scale applications. The ease of application and the self-healing properties make these coatings an attractive option for various industries, from construction to automotive. As Marotta notes, “The produced epoxy vitrimers are able to provide extended service life while maintaining good protective performance and self-repairability.”

This breakthrough could shape the future of the coatings industry, driving innovation and opening up new possibilities for self-healing materials. As researchers continue to explore the potential of vitrimers, we can expect to see more advancements in this field, paving the way for smarter, more durable, and more sustainable materials.