In the rapidly evolving world of dental and medical technologies, a groundbreaking study has emerged that could significantly enhance the adhesion of high-strength polymers used in dental reconstructions. Published in the journal *Macromolecular Materials and Engineering* (which translates to *Macromolecular Engineering Materials* in English), the research led by William T. Lewin from the Arto Hardy Family Biomedical Innovation Hub at Chris O’Brien Lifehouse in Australia, focuses on the application of plasma immersion ion implantation (PIII) to improve the bond strength of poly-aryl-ether-ketone (PAEK) polymers with dental composite resin cements.

PAEK polymers, including Polyether-ether-ketone (PEEK) and Poly-ether-ketone (PEK), are renowned for their high strength and are increasingly used in personalized dental and mandibular reconstructions. However, their smooth surfaces have posed challenges in achieving strong adhesive bonds with dental composites, which are crucial for the longevity and effectiveness of these medical devices.

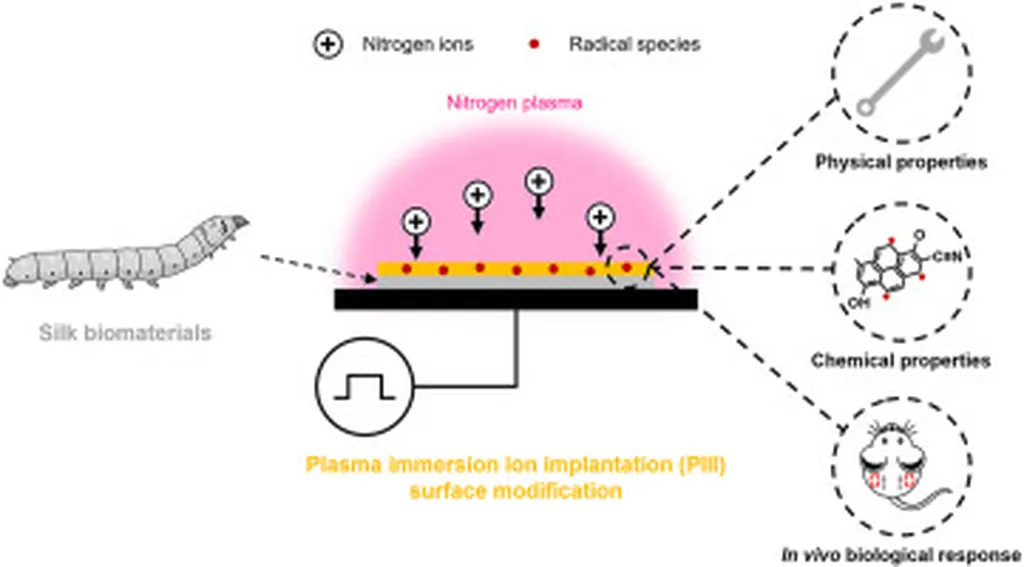

The study demonstrates that PIII significantly enhances the bond strength between PAEK polymers and dental composite resin cements, regardless of the surface roughness. This advancement is particularly noteworthy because it eliminates the need for a primer step, which has been linked to hydrolysis-induced weakening over time. “The bond strength achieved using PIII is retained even when the primer step is omitted,” notes Lewin, highlighting the robustness of this new method.

One of the most compelling aspects of this research is the predictive model developed to understand the bond strength as a function of surface roughness. This model not only showcases the relative effects of PIII and mechanical interlocking but also provides a valuable tool for future advancements in the field. The long-term water immersion test further solidifies the findings, showing that PIII-assisted, primer-free bonds maintain their strength, unlike primer-assisted bonds that weaken over time.

The implications of this research extend beyond the dental industry. The enhanced adhesion and durability of PAEK polymers could revolutionize the manufacturing of medical devices, ensuring better performance and longevity. For the energy sector, where high-strength polymers are also utilized, this technology could lead to more reliable and efficient components, particularly in harsh environments where hydrolysis resistance is critical.

As the medical and energy sectors continue to seek innovative solutions, this study paves the way for future developments. By addressing the fundamental challenges of adhesion and durability, PIII technology could become a cornerstone in the design and production of next-generation materials. The research not only offers immediate practical benefits but also opens new avenues for exploration and innovation in material science.

In summary, the work of William T. Lewin and his team represents a significant leap forward in the field of polymer adhesion. Their findings, published in *Macromolecular Materials and Engineering*, provide a robust solution to long-standing challenges and set the stage for future advancements that could transform both the medical and energy sectors.