In the quest for sustainable solutions in the rubber industry, a groundbreaking study led by Vanessa Spanheimer from TH Köln in Germany has shed light on the potential of recycled carbon black as a viable substitute for traditional, fossil-based carbon black in Ethylene Propylene Diene Monomer (EPDM) elastomers. Published in the journal *Macromolecular Materials and Engineering*, the research explores the thermo-oxidative aging and performance of recovered carbon black (rCB) and sustainable carbon black (sCB) in EPDM-based sealing compounds.

The study is a significant step forward in addressing the environmental challenges posed by end-of-life tires, which are often discarded or incinerated, contributing to pollution and waste. Pyrolysis, a process that decomposes materials at high temperatures in the absence of oxygen, offers a promising recycling solution. This process yields two valuable byproducts: sCB, derived from pyrolysis oil, and rCB, the solid residue.

Spanheimer and her team investigated the feasibility of partially or fully replacing industrial carbon black (N550) with sCB and rCB in EPDM sealing compounds. The results are intriguing. “sCB is very close to N550 as a raw material and in terms of its in-rubber properties,” Spanheimer noted. This suggests that sCB could seamlessly integrate into existing manufacturing processes, offering a sustainable alternative without compromising performance.

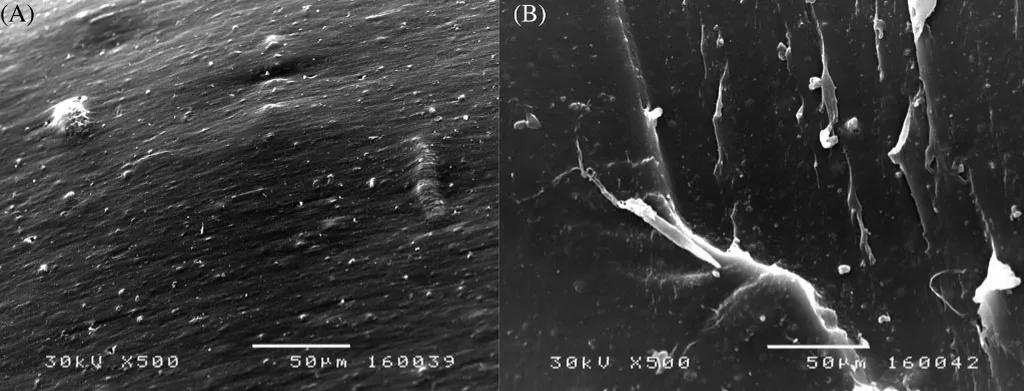

However, rCB presents a different story. The presence of impurities in rCB alters the cross-linking density and structure of the polymer-sulfur network, shifting towards a polysulfidic structure. This alteration leads to lower reinforcement and weaker polymer-filler interactions, with a notable decrease of 43% in the I3/1 ratio compared to virgin carbon black (vCB). “Aging effects are also more pronounced in the compounds containing rCB,” Spanheimer added, highlighting the need for further optimization.

The commercial implications for the energy sector are substantial. EPDM elastomers are widely used in sealing applications, including in energy infrastructure, where durability and performance under extreme conditions are critical. The adoption of sCB could significantly reduce the carbon footprint of these materials, aligning with the industry’s sustainability goals. Moreover, the findings pave the way for future research into optimizing rCB for use in less demanding applications, further expanding the potential for recycled materials in the rubber industry.

As the world grapples with the challenges of circular economy and sustainable practices, this research offers a glimmer of hope. It underscores the importance of continued innovation and collaboration in developing eco-friendly solutions that do not compromise on performance. The journey towards a sustainable future is complex, but with each breakthrough, we inch closer to a world where waste is minimized, and resources are used more efficiently.