In the quest for cleaner energy solutions, scientists are turning to water electrolysis as a promising method to produce hydrogen, a versatile energy carrier. However, the process faces significant hurdles, particularly in reaction kinetics, which slow down its industrial adoption. A recent review published in *Materials Futures* (translated to English as “Materials Horizons”) sheds light on a promising avenue to overcome these challenges: porous metal-based catalysts.

Led by Yaqi Yue, a researcher at the Key Laboratory of Superlight Materials and Surface Technology of Ministry of Education, College of Materials Science and Chemical Engineering, Harbin Engineering University, and the Qingdao New Energy Shandong Laboratory, Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences, the review explores how porous nanostructures can enhance catalytic performance. These structures increase active areas, provide abundant active centers, and create open transmission channels, all crucial for improving the efficiency of water electrolysis.

“Designing porous nanostructures has emerged as an effective strategy for boosting catalytic performance,” Yue explains. “By creating more active sites and facilitating better mass transport, we can significantly reduce the energy required for the hydrogen evolution reaction and the oxygen evolution reaction.”

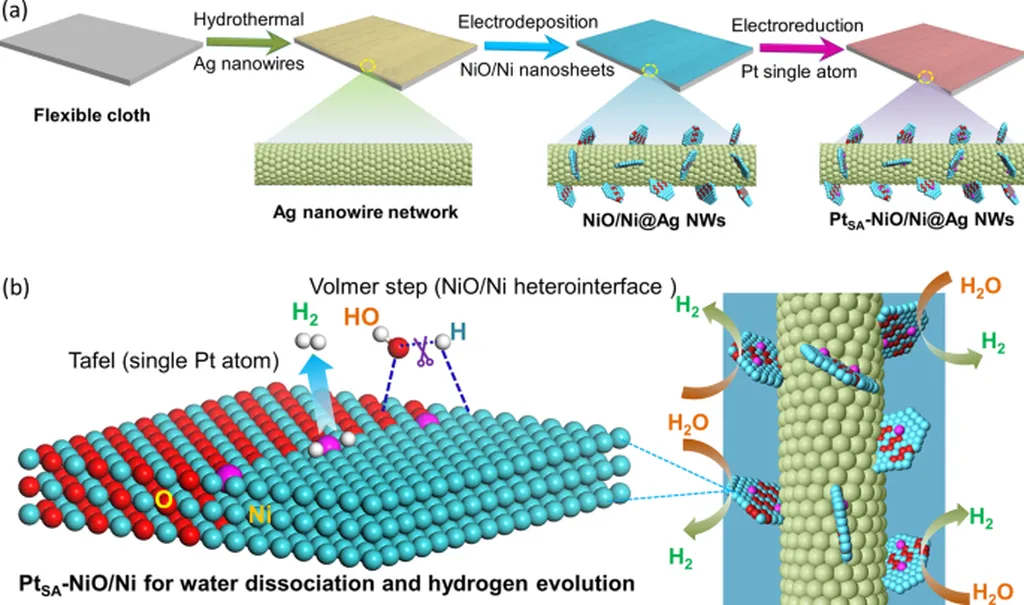

The review highlights recent advancements in porous electrocatalysts composed of both noble and transition metals. Noble metals, such as platinum and iridium, have long been favored for their excellent catalytic properties. However, their high cost and rarity limit widespread use. Transition metals, on the other hand, offer a more cost-effective alternative. The study provides feasible strategies and inspiration for designing water electrolytic catalysts, paving the way for more efficient and affordable hydrogen production.

The implications for the energy sector are substantial. Hydrogen, produced through water electrolysis, can be used as a clean fuel for various applications, from powering vehicles to heating homes. By improving the efficiency of the electrolysis process, these porous metal-based catalysts could make hydrogen a more viable and competitive energy source.

“Our goal is to make hydrogen production more efficient and cost-effective,” Yue says. “This review provides a roadmap for future research and development in this field, highlighting the potential of porous metal-based catalysts to revolutionize the energy landscape.”

The review also addresses existing challenges and future development prospects for porous catalysts in water electrolysis. While significant progress has been made, there is still much work to be done to optimize these catalysts and scale up their production for industrial use.

As the world seeks to transition to cleaner energy sources, the research published in *Materials Futures* offers a glimpse into the future of hydrogen production. By leveraging the unique properties of porous metal-based catalysts, scientists are edging closer to making water electrolysis a practical and sustainable solution for the energy sector.