In a significant stride toward enhancing the performance of medical implants, researchers have developed a novel bioglass–iron oxide composite coating that promises to revolutionize the durability and bioactivity of titanium alloys. The study, led by Zahra Sohani from the Department of Materials Engineering at Babol Noshirvani University of Technology in Iran, explores the structural and functional properties of these composite layers, offering a glimpse into the future of implant technology.

The research, published in *Composites Part C: Open Access* (which translates to *Composites Part C: Open Access* in English), focuses on the electrophoretic deposition (EPD) of bioglass–iron oxide (Fe₃O₄) composite layers on Ti-6Al-4V substrates. By varying the Fe₃O₄ content in the suspensions, the team identified the optimal composition for achieving superior coatings. The B90-F10 sample, containing 90% bioglass and 10% Fe₃O₄, emerged as the standout performer, delivering a more uniform and denser coating with minimal porosity and crack formation.

“The B90-F10 coating not only exhibited enhanced mechanical properties but also demonstrated improved surface characteristics and bioactivity,” Sohani explained. “This makes it a promising candidate for applications in the medical field, particularly for implants that require both durability and biocompatibility.”

The Vickers microhardness of the B90-F10 coating reached 321.3 ± 3.4 HV, surpassing that of the pure bioglass coating (295.1 ± 2.3 HV). Additionally, the surface roughness of B90-F10 was significantly lower, indicating a smoother and more compact surface. The mean coating thickness for B90-F10 was also slightly greater than that of the pure bioglass coating, further enhancing its protective capabilities.

One of the most compelling aspects of this research is its potential impact on the energy sector. While the immediate applications are in medical implants, the principles and technologies developed here could be adapted for use in other industries. For instance, the enhanced corrosion resistance and improved barrier performance of these composite coatings could be beneficial in the development of more durable and efficient energy storage devices, such as batteries and supercapacitors.

“Our findings highlight the coatings’ capacity to augment implant performance by improving mechanical durability, surface characteristics, and bioactivity,” Sohani noted. “This offers a valuable functional enhancement beyond the untreated substrate, which could have far-reaching implications for various industries.”

The study also confirmed the improved hydrophilicity of the B90-F10 coating, with a reduced contact angle compared to the uncoated substrate. Electrochemical tests revealed that while the coatings slightly reduced corrosion resistance compared to bare alloy due to residual porosity, the addition of Fe₃O₄ significantly increased charge transfer resistance, indicating better barrier performance than pure bioglass coatings.

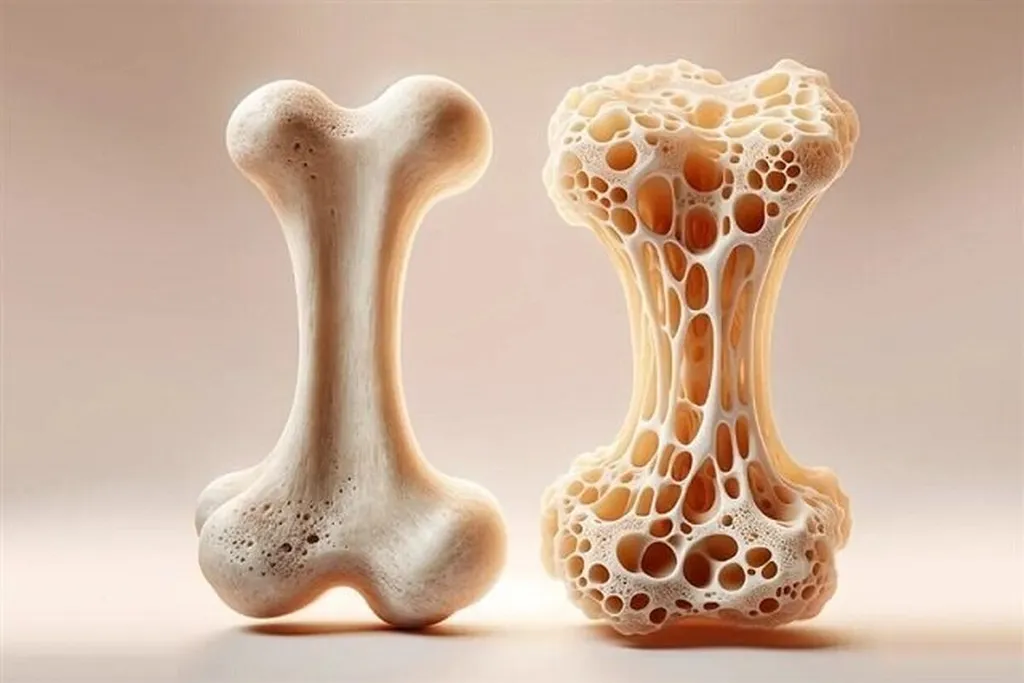

In vitro bioactivity tests further confirmed the enhanced formation of hydroxyapatite layers, which are critical for osseointegration. This means that the coatings could significantly improve the integration of implants with bone tissue, leading to better patient outcomes and reduced recovery times.

As the energy sector continues to evolve, the demand for materials that can withstand harsh environments while maintaining their structural integrity and functionality is growing. The research conducted by Sohani and her team offers a promising avenue for developing such materials, with potential applications ranging from medical implants to energy storage devices.

“This research not only advances our understanding of composite coatings but also opens up new possibilities for their application in various industries,” Sohani concluded. “By optimizing the composition and deposition process, we can create materials that are not only more durable but also more functional, paving the way for innovative solutions in the energy sector and beyond.”

With its focus on enhancing the performance of titanium alloys through advanced composite coatings, this study represents a significant step forward in the field of materials science. As researchers continue to explore the potential of these coatings, we can expect to see a range of new applications emerge, driving innovation and progress in both the medical and energy sectors.