In the quest to bolster the reliability of laser beam welding for aluminium alloys, researchers have turned to an innovative solution: nanoparticles. A recent study published in the *Journal of Advanced Joining Processes* (translated as “Journal of Advanced Joining Processes”) explores how alumina (Al2O3) and titanium carbide (TiC) nanoparticles can significantly enhance the integrity of welds in AA6005 aluminium alloys, a material widely used in the energy sector.

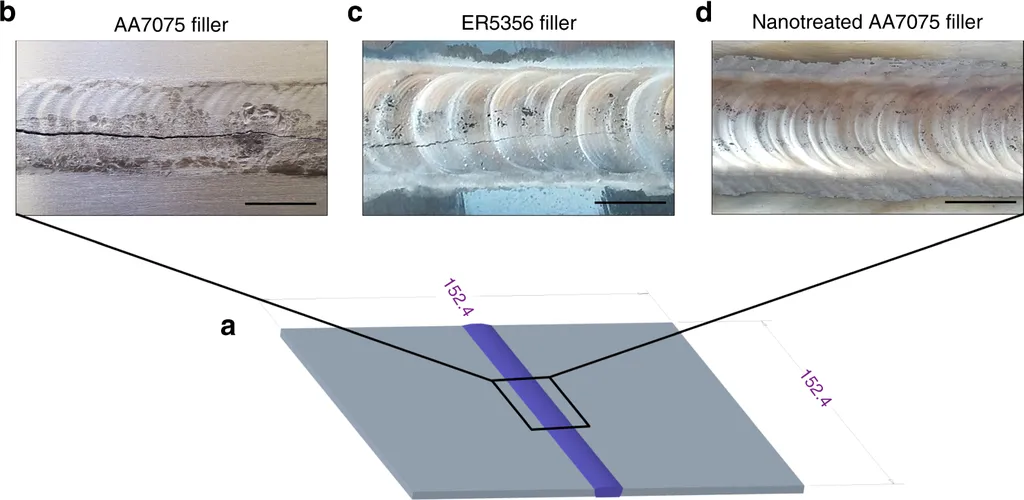

Laser beam welding is a critical joining method for wrought 6xxx series aluminium alloys, but its broader adoption has been hindered by solidification cracking, which compromises weld integrity and limits the production of high-quality joints. To address this challenge, researchers led by M.H. Khan from WMG, The University of Warwick, UK, introduced nanoparticles into the fusion zone of laser-welded AA6005 aluminium sheets using electrophoretic deposition.

The study revealed that incorporating both Al2O3 and TiC nanoparticles led to a remarkable 65% grain refinement, effectively preventing centreline cracking during welding. “This grain refinement is crucial because it directly impacts the mechanical properties and overall strength of the weld,” Khan explained.

Lap shear testing demonstrated significant improvements in joint strength. Samples coated with Al2O3 showed a 10% increase in strength, while those coated with TiC exhibited a 13% increase compared to uncoated material. Notably, TiC outperformed Al2O3 at higher concentrations, exhibiting more uniform dispersion with reduced agglomeration and porosity. “TiC nanoparticles showed a more consistent performance, which is essential for ensuring the reliability of the welding process,” Khan noted.

However, Al2O3 had its own challenges. At elevated concentrations, it tended to cluster and form pores, limiting its strengthening efficiency. This highlights the importance of optimizing nanoparticle concentration and deposition parameters to achieve the best results.

The implications of this research are profound for the energy sector, where aluminium alloys are widely used in various applications, from renewable energy infrastructure to transportation. Enhancing the reliability of laser beam welding can lead to more robust and efficient manufacturing processes, ultimately reducing costs and improving product performance.

As the energy sector continues to evolve, the demand for high-quality, reliable materials and joining techniques will only grow. This study paves the way for further advancements in nanoparticle reinforcement, offering a promising solution to the long-standing challenge of solidification cracking in aluminium alloys.

In the words of Khan, “This research is just the beginning. We are excited about the potential of nanoparticles to revolutionize the welding industry and contribute to the development of more sustainable and efficient energy solutions.”