In the world of structural engineering, the humble steel plate is a workhorse, but what happens when you start poking holes in it? A recent study published in *Jianzhu Gangjiegou Jinzhan* (Advances in Structural Steel Construction) has taken a deep dive into this very question, with implications that could resonate through the energy sector and beyond. Led by Li Pengfei, the research explores how different hole patterns affect the shear capacity of steel plates, offering insights that could influence everything from offshore wind farms to industrial infrastructure.

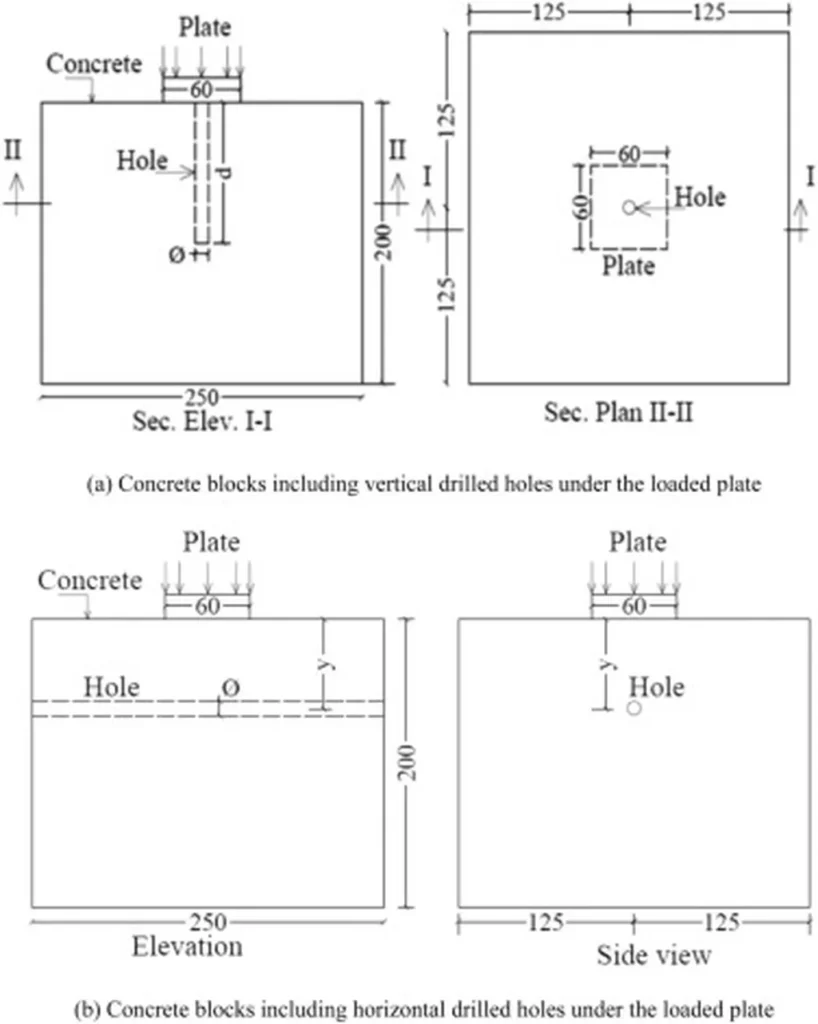

Li Pengfei and his team used ANSYS finite element software to model the behavior of perforated steel plates under shear loads. The study validated their models against experimental data, ensuring accuracy before exploring how factors like hole position, shape, aspect ratio, and material strength affect shear capacity. “We found that while the shape of the holes does have an impact, it’s relatively minor,” Li explains. “The real game-changer is where you put those holes.”

The research revealed that holes in the center of the plate significantly reduce shear capacity, while holes near the corners have a much smaller effect. “The center is the most critical area,” Li notes. “If you’re designing structures with perforated steel plates, you need to be strategic about where you place those holes.” The study also found that the volume of the holes—rather than their aspect ratio—was a better predictor of how much they would weaken the plate. Interestingly, the material’s strength didn’t seem to influence the degree of degradation caused by the holes.

For the energy sector, these findings could be a boon. Offshore wind farms, for example, often use perforated steel plates in their foundations to reduce weight and cost. Understanding how to optimize hole placement could lead to safer, more efficient designs. Similarly, in the oil and gas industry, where steel structures are subjected to extreme forces, this research could help engineers balance the need for lightweight materials with the demands of structural integrity.

The study also employed response surface methodology to develop a regression equation that predicts how hole position and size affect shear capacity. This tool could be a valuable asset for engineers looking to fine-tune their designs. “Our goal was to provide a practical framework for evaluating the performance of perforated steel plates,” Li says. “We hope this research will help engineers make more informed decisions in their designs.”

As the energy sector continues to push the boundaries of engineering, research like this is crucial. It’s not just about innovation; it’s about understanding the fundamentals and applying them in smarter, more efficient ways. Li’s work offers a glimpse into the future of structural engineering, where every hole has a purpose, and every design is optimized for performance. For professionals in the field, the message is clear: when it comes to perforated steel plates, location is everything.