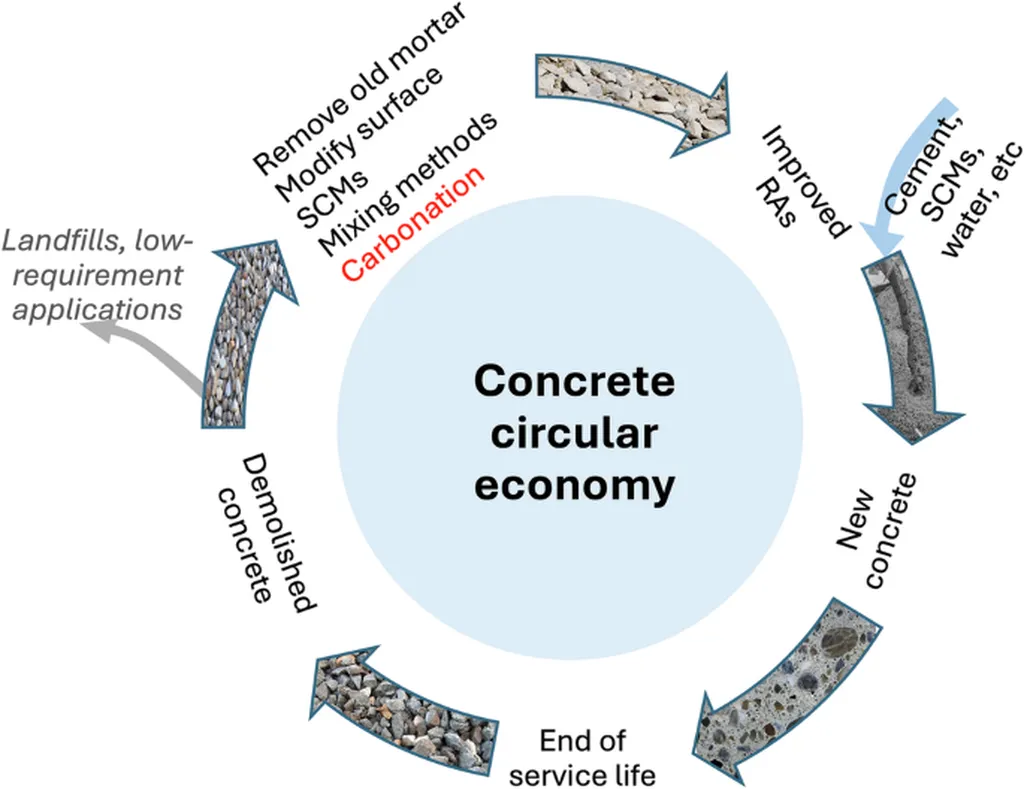

In a groundbreaking study published in the journal *npj Materials Sustainability* (translated to English as *Nature Partner Journal Materials Sustainability*), researchers have uncovered promising insights into the durability performance of concrete incorporating carbonated recycled coarse aggregates (RAs). The research, led by Zhidong Zhang from the Institute for Building Materials at ETH Zurich, sheds light on how carbonation can significantly enhance the quality of recycled aggregates, offering a sustainable and cost-effective solution for the construction industry.

The study reveals that concrete made with carbonated recycled aggregates (cRAC) shows improved durability indicators compared to concrete with non-carbonated RAs. “All durability indicators of cRAC are improved by 13–55% because of the densified microstructure after carbonation,” Zhang explains. This enhancement is attributed to the carbonation process, which densifies the microstructure of the aggregates, making them more robust and durable.

While cRAC still falls short of the durability performance of natural aggregate concrete, the improvements are substantial enough to make a significant impact in the industry. The research suggests that optimized carbonation methods, such as adjusting moisture content and using biomaterials, could further improve the quality of carbonated RAs.

The commercial implications for the energy sector are substantial. As the demand for sustainable construction materials grows, the ability to enhance the durability of recycled aggregates through carbonation presents a viable alternative to traditional materials. This could lead to reduced costs and environmental impact, as well as increased efficiency in construction projects.

“The potential to improve the quality of recycled aggregates through carbonation is a game-changer,” says Zhang. “It not only addresses the environmental concerns associated with traditional aggregate production but also offers a more sustainable and cost-effective solution for the construction industry.”

As the construction industry continues to seek innovative solutions to reduce its environmental footprint, this research provides a compelling case for the adoption of carbonated recycled aggregates. The findings could shape future developments in the field, paving the way for more sustainable and durable construction materials.

Published in *npj Materials Sustainability*, this study offers a glimpse into the future of construction materials, highlighting the potential of carbonation to revolutionize the industry. As researchers continue to explore optimized carbonation methods, the possibilities for enhancing the durability and sustainability of construction materials are endless.