In the quest to enhance the performance of magnesium alloys, a team of researchers led by Guojun Liu from the School of Materials Science and Engineering at the University of Science and Technology Beijing has made a significant breakthrough. Their study, published in the journal *Materials Research* (translated from Portuguese, *Revista Materiais de Construção*), focuses on the effects of minor cerium (Ce) additions on the microstructure, tensile properties, and corrosion resistance of Mg–7.5Al–2Sn–1Zn (ATZ721) alloys. The findings could have profound implications for the energy sector, particularly in applications requiring lightweight, high-strength materials.

Magnesium alloys are prized for their lightweight and high strength-to-weight ratio, making them ideal for various industrial applications, including automotive and aerospace components. However, their widespread adoption has been hindered by issues related to mechanical properties and corrosion resistance. Liu and his team sought to address these challenges by investigating the impact of adding small amounts of cerium to the ATZ721 alloy.

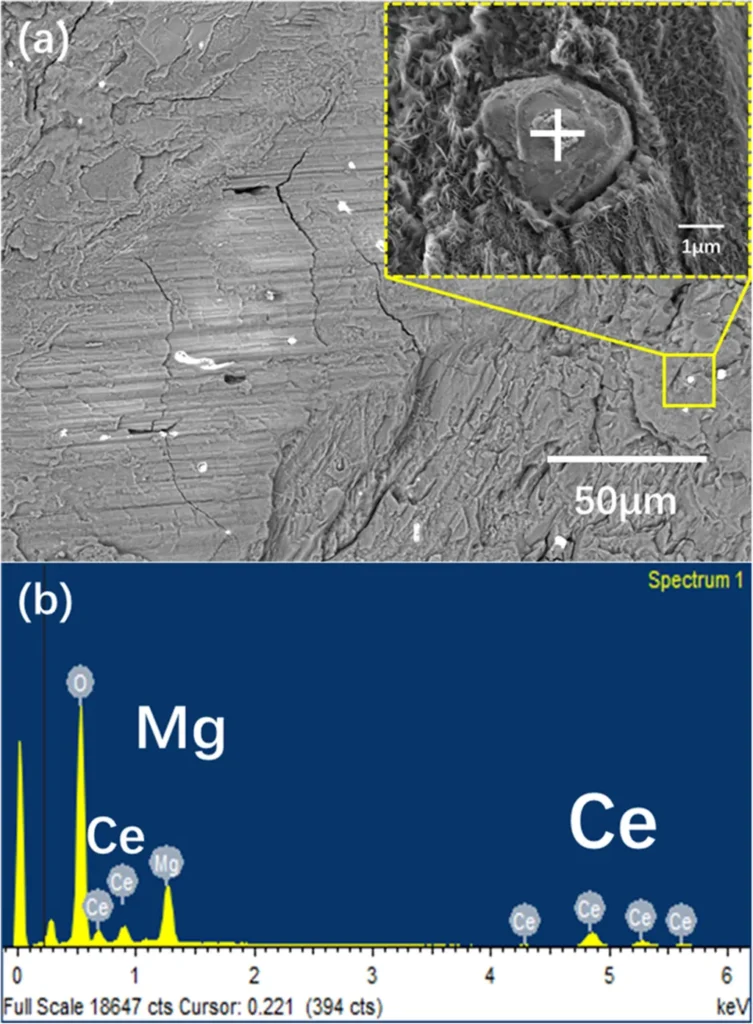

The researchers found that the addition of cerium leads to the formation of the Al4Ce phase, which reduces the volume fraction of the Mg17Al12 phase and refines the microstructure. This refinement translates into significant improvements in mechanical properties. “The alloy with 1.0 wt.% Ce showed superior performance with an ultimate tensile strength (UTS) of 237 MPa, yield strength (YS) of 98 MPa, and elongation to failure (Ef) of 16.7% at room temperature,” Liu explained. These improvements represent a 22% increase in UTS, a 17% increase in YS, and a 52% increase in elongation to failure compared to the base alloy.

In addition to enhanced mechanical properties, the researchers observed a notable improvement in corrosion resistance. The alloy with 1.0 wt.% Ce exhibited a corrosion rate of 1.8 mm/yr in a 3.5 wt.% NaCl solution, significantly lower than the base alloy’s 8.4 mm/yr. This finding is particularly relevant for the energy sector, where materials are often exposed to harsh environments and need to maintain their integrity over extended periods.

The implications of this research are far-reaching. “The enhanced properties of these alloys could lead to the development of more durable and efficient components for various applications, including automotive and aerospace industries,” Liu noted. The improved corrosion resistance and mechanical properties could also make these alloys more suitable for use in renewable energy systems, such as wind turbines and solar panels, where lightweight and durable materials are crucial.

As the energy sector continues to evolve, the demand for advanced materials that can withstand demanding conditions while maintaining high performance is growing. The research conducted by Liu and his team represents a significant step forward in this area, offering a promising solution to some of the longstanding challenges associated with magnesium alloys.

The study, published in *Materials Research*, highlights the potential of minor cerium additions to transform the properties of Mg–Al–Sn–Zn alloys. As the energy sector seeks to adopt more sustainable and efficient materials, this research could pave the way for innovative applications that leverage the unique advantages of these enhanced alloys. The findings not only advance our understanding of material science but also open new avenues for technological advancements in the energy sector.