In a significant stride towards sustainable construction, researchers have developed a deep learning model that could revolutionize the way geopolymer concrete (GPC) is designed and utilized, particularly in the energy sector. This innovation, led by Yang Yu from the Centre for Infrastructure Engineering and Safety at the University of New South Wales, offers a promising solution to predict the compressive strength of fly ash and slag-based GPC with remarkable accuracy.

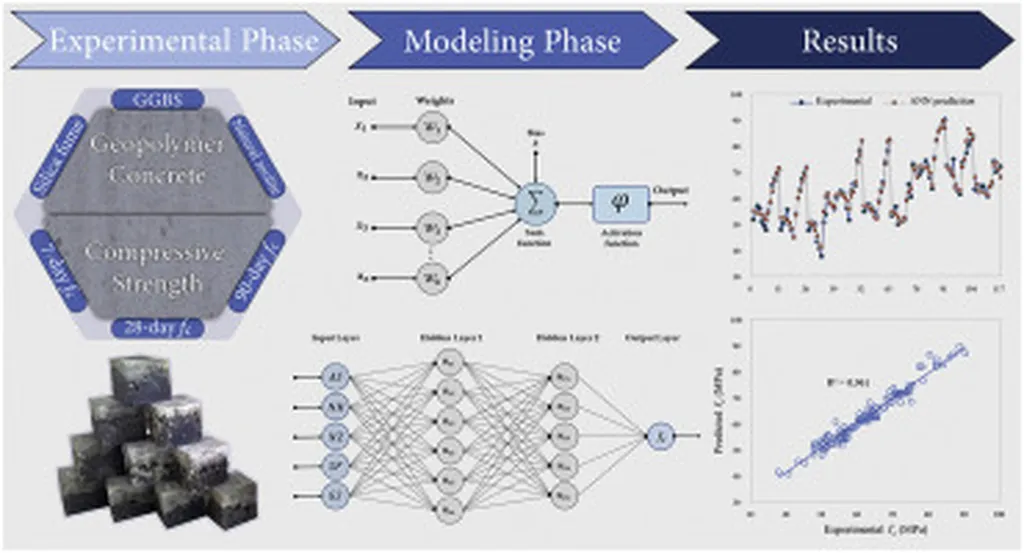

Geopolymer concrete, a sustainable alternative to traditional Portland cement concrete, uses industrial by-products like fly ash and ground-granulated blast-furnace slag (GGBS). However, optimizing its compressive strength has traditionally required extensive and costly experimental trials. Yu’s research introduces a deep learning model based on convolutional neural networks (CNN) that integrates key mix parameters and chemical compositions, making it chemistry-informed.

“The model not only predicts the compressive strength but also identifies the most influential factors affecting it,” Yu explained. “This level of insight is crucial for optimizing the mix design and performance evaluation of GPC.”

The model’s architecture includes two convolution layers, global max-pooling, and two fully connected layers, with 11 input variables and a single output for compressive strength prediction. To enhance accuracy, the enhanced bat algorithm (EBA) was used for metaparameter tuning. The results were impressive, with the EBA-optimised CNN outperforming traditional learning models like support vector machine (SVM), extreme gradient boosting (XGBoost), and artificial neural networks (ANN). The model achieved R2 values of 0.997 for training and 0.978 for testing.

“This research demonstrates the potential of deep learning techniques in the construction industry,” said Yu. “By providing a cost-effective and accurate solution for predicting the strength of GPC, we can significantly reduce the time and resources required for mix design and performance evaluation.”

The study, published in the journal ‘Developments in the Built Environment’ (translated as ‘建筑环境发展’), highlights the importance of integrating advanced technologies in sustainable construction practices. The Shapley additive explanations (SHAP) method was used to interpret the model, identifying the Na2O to binder ratio and curing age as the most influential factors on compressive strength.

As the energy sector increasingly focuses on sustainability and reducing carbon footprints, the adoption of geopolymer concrete is expected to grow. This research provides a robust tool for optimizing GPC, making it a more viable and attractive option for large-scale construction projects. By leveraging deep learning and advanced algorithms, the construction industry can achieve greater efficiency, cost savings, and environmental benefits.

“This is just the beginning,” Yu added. “As we continue to refine and expand the model, we anticipate even greater advancements in the field of sustainable construction.” The implications of this research extend beyond the construction industry, offering valuable insights for researchers, engineers, and policymakers working towards a more sustainable future.