In the quest to create more versatile and durable materials, researchers have made a significant stride in blending thermoplastic polyurethane (TPU) with natural rubber (NR), a combination that promises to revolutionize industries from automotive to medical devices. The key to this breakthrough? A compatibilizer called epoxidized natural rubber (ENR), which acts as a molecular matchmaker, enhancing the bond between TPU and NR. This research, led by Torfan Srisuwanno, was recently published in the journal eXPRESS Polymer Letters, which translates to “Express Polymer Letters” in English.

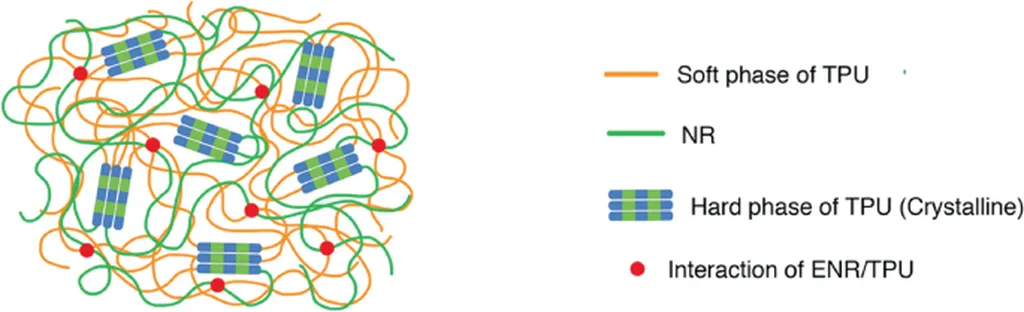

The study addresses a longstanding challenge in polymer science: blending TPU, known for its excellent mechanical properties and flexibility, with NR to create thermoplastic natural rubber (TPNR). While the combination offers a unique blend of elasticity and processability, phase incompatibility has historically limited its potential. “The incompatibility between TPU and NR often results in reduced mechanical strength and thermal stability,” explains Srisuwanno. “Our goal was to find a way to improve this compatibility and unlock the full potential of these blends.”

The solution came in the form of ENR, which has a hydrocarbon backbone that interacts with crosslinked NR and epoxy groups that enhance adhesion with TPU. By incorporating just 3 parts per hundred rubber (phr) of ENR, the researchers observed a significant improvement in the material’s properties. “We saw a 41.1% increase in tensile strength, enhanced stress relaxation, and a lowering of the glass transition temperatures for both TPU and NR phases,” says Srisuwanno. “This is a clear indication of improved chemical bridging between the two polymers.”

However, the researchers also found that too much of a good thing can be detrimental. Excess ENR disrupts phase compatibility, causing polymer entanglement and reduced strength. “It’s all about finding the right balance,” Srisuwanno notes. “Optimizing the ENR content is crucial for developing high-performance TPU/NR blends.”

The implications of this research are far-reaching. The enhanced TPU/NR blends could find applications in a wide range of industries, from automotive and construction to medical devices. For instance, the improved flexibility and durability could make these materials ideal for creating flexible splints and other medical devices. The study also demonstrated the printability of these materials using material extrusion additive manufacturing (MEx-AM) fused deposition modeling (FDM), opening up new possibilities for 3D printing applications.

In the energy sector, these advanced materials could contribute to the development of more efficient and durable components for renewable energy technologies. As the world continues to shift towards sustainable energy solutions, the need for innovative materials that can withstand harsh conditions and provide long-lasting performance is more critical than ever.

This research not only sheds light on the potential of ENR as a compatibilizer but also paves the way for future developments in polymer science. As Srisuwanno puts it, “Our findings provide a solid foundation for further exploration and optimization of TPU/NR blends, potentially leading to the development of new materials with tailored properties for specific applications.”

In the ever-evolving landscape of materials science, this study stands as a testament to the power of innovation and the potential of interdisciplinary research. As industries continue to seek out more versatile and sustainable materials, the enhanced TPU/NR blends developed by Srisuwanno and his team could very well be at the forefront of this exciting journey.