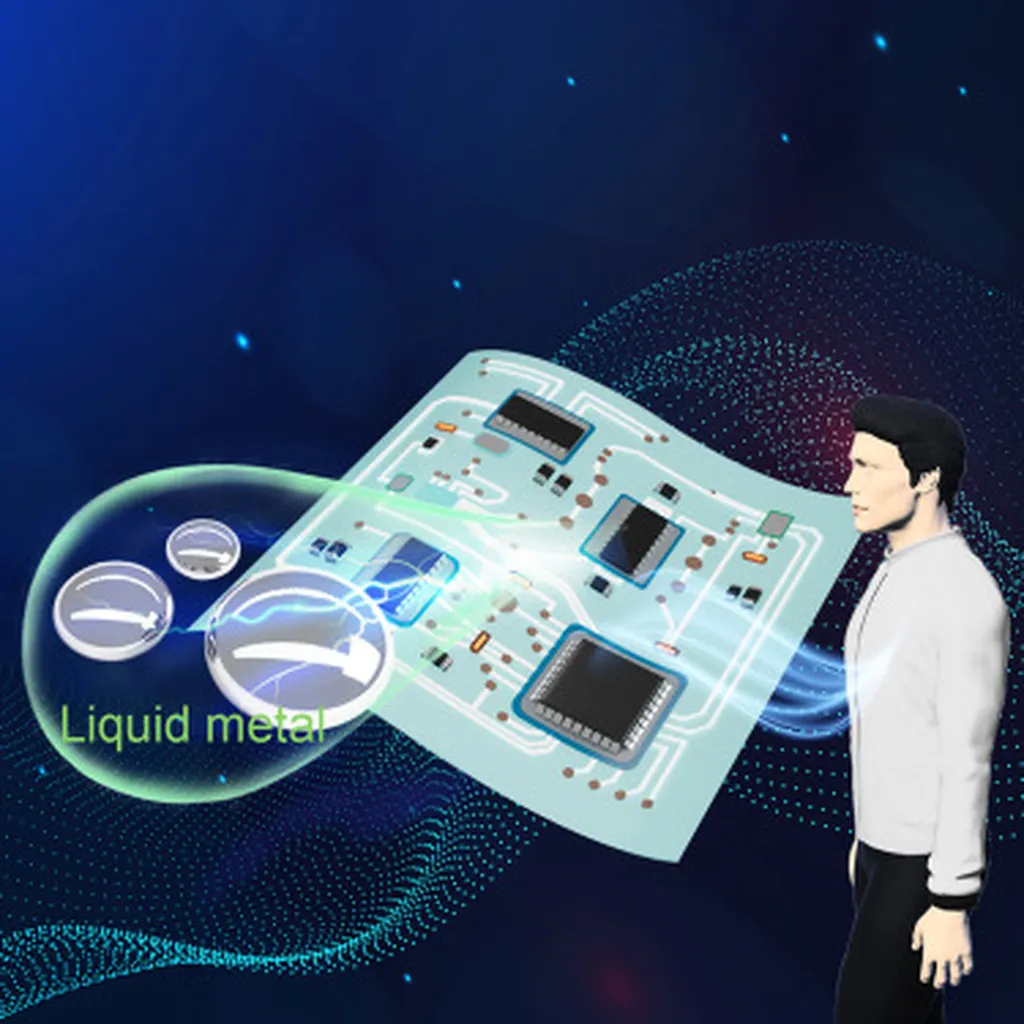

In the rapidly evolving world of flexible electronics, a groundbreaking study published in *InfoMat* (translated from Chinese as “Information Materials”) is shedding new light on the adhesion mechanisms of liquid metals to various substrates. This research, led by Chunxue Wan from the State Key Laboratory of Cryogenic Science and Technology at the Technical Institute of Physics and Chemistry, Chinese Academy of Sciences, could revolutionize the way we think about printed electronics and their applications in the energy sector.

Liquid metals, known for their exceptional electrical conductivity and room-temperature fluidity, are increasingly being used in the development of flexible and stretchable electronics. However, until now, the adhesion mechanisms at the interface between liquid metals and substrates have not been fully understood. This gap in knowledge has been a significant barrier to the widespread adoption of liquid metal-based printed electronics.

In their comprehensive review, Wan and her team delve into the fundamental properties of liquid metals and their adhesion mechanisms to various substrates. They explore printing technologies designed to enhance or reduce substrate adhesion, as well as techniques for printing on non-adhesive substrates through material modification. Moreover, they discuss methods for achieving detachment on adhesive substrates by controlling interfacial properties.

“The adhesion between liquid metals and substrates is a critical factor in the performance and durability of flexible electronic devices,” Wan explains. “By understanding and controlling these adhesion mechanisms, we can open up new possibilities for the application of liquid metal-based electronics in various industries, including the energy sector.”

The implications of this research are far-reaching. In the energy sector, for instance, flexible electronics can be used in the development of wearable energy harvesting devices, smart grids, and flexible solar cells. By improving the adhesion of liquid metals to various substrates, we can enhance the efficiency and reliability of these devices, paving the way for more sustainable and innovative energy solutions.

Wan’s team also highlights future research challenges and developmental trends in materials, methods, equipment, and applications. They emphasize the need for further exploration of the interfacial adhesion effects between liquid metals and substrates, which could lead to the development of new materials and technologies with even broader applications.

As we look to the future, the insights provided by this research could shape the development of next-generation flexible electronics, driving innovation and progress in the energy sector and beyond. By unraveling the mysteries of liquid metal adhesion, Wan and her team have taken a significant step forward in our understanding of this exciting field.

In the words of Wan, “This review provides a comprehensive understanding of the interfacial adhesion effects between liquid metals and substrates, offering valuable insights for printing on a wide range of substrates, including plastics, silicones, paper, and even biological surfaces.” With these insights, the possibilities for innovation in flexible electronics are truly limitless.