In the quest for sustainable and high-performance materials, researchers have turned to an unlikely source: the oil palm trunk. A recent study published in the journal *eXPRESS Polymer Letters* (which translates to “Rapid Polymer Letters”) explores the potential of using oil palm trunk (OPT) components to reinforce polypropylene (PP) composites, offering promising insights for the energy sector and beyond.

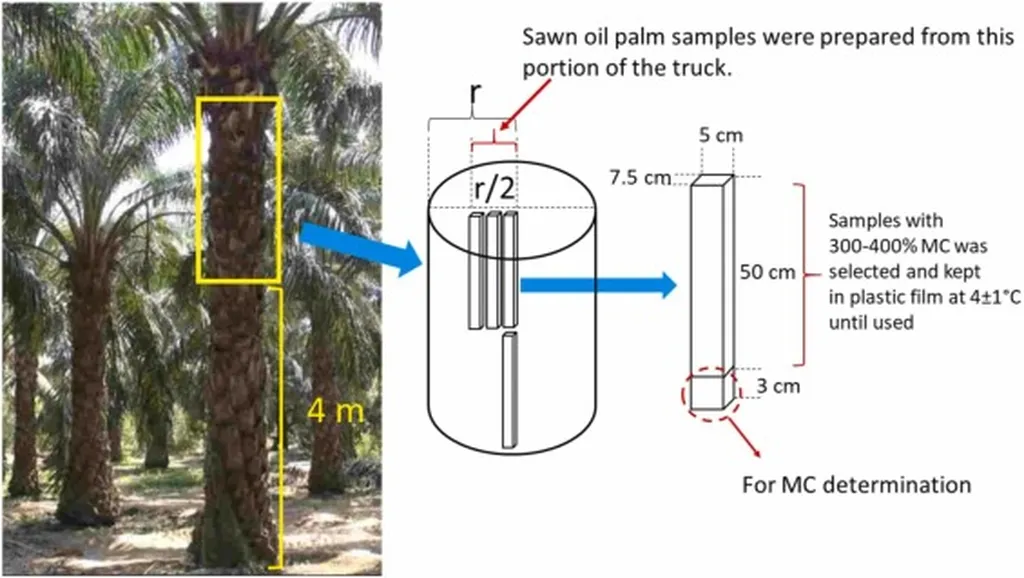

Led by Kanokorn Sae-Ueng, the research delves into the mechanical properties and water resistance of PP composites reinforced with vascular bundles (VB) and parenchyma cells (PC) particles from oil palm trunks. The study addresses the challenges posed by the inherent variability in density and moisture sensitivity of OPT, which has previously hindered its use in composite formulation.

“Our goal was to understand how different components of the oil palm trunk could enhance the performance of polypropylene composites,” said Sae-Ueng. “We found that both vascular bundles and parenchyma cells significantly improved the mechanical properties and water resistance of the composites compared to untreated OPT.”

The research team utilized a hot-pressing technique to examine the effects of OPT type, filler content, and the addition of a maleic anhydride-grafted polypropylene (MAPP) coupling agent. The findings reveal that increasing the OPT content improves the modulus and density of the composites but negatively impacts tensile and flexural strengths due to poor interfacial bonding. However, the incorporation of MAPP significantly enhances interfacial adhesion between the PP matrix and OPT fillers, leading to reduced moisture uptake and dimensional swelling, particularly at higher filler loadings.

“This study highlights the potential of vascular bundles and parenchyma cells as sustainable reinforcement materials for wood-plastic composites (WPC),” said Sae-Ueng. “By optimizing the composite design, we can improve durability and water resistance, making these materials more viable for commercial applications.”

The implications of this research are far-reaching, particularly for the energy sector, where sustainable and durable materials are in high demand. As the world shifts towards renewable energy sources, the need for eco-friendly and high-performance materials will only grow. The use of oil palm trunk components in PP composites could provide a sustainable solution for various applications, from construction materials to energy infrastructure.

“This research opens up new possibilities for the use of natural fibers in composite materials,” said Sae-Ueng. “By leveraging the unique properties of oil palm trunk components, we can create materials that are not only sustainable but also highly performant.”

As the energy sector continues to evolve, the development of sustainable and high-performance materials will be crucial. The research led by Kanokorn Sae-Ueng offers a promising path forward, demonstrating the potential of oil palm trunk components in enhancing the properties of polypropylene composites. With further optimization and commercialization, these materials could play a significant role in shaping the future of the energy sector and beyond.