In a groundbreaking development poised to reshape the construction and energy sectors, researchers have successfully electrospun epoxy fibers, unlocking unprecedented mechanical properties that could revolutionize composite materials. The study, led by Mark Shneider, was recently published in the journal “eXPRESS Polymer Letters,” which translates to “Polymer Letters Express” in English.

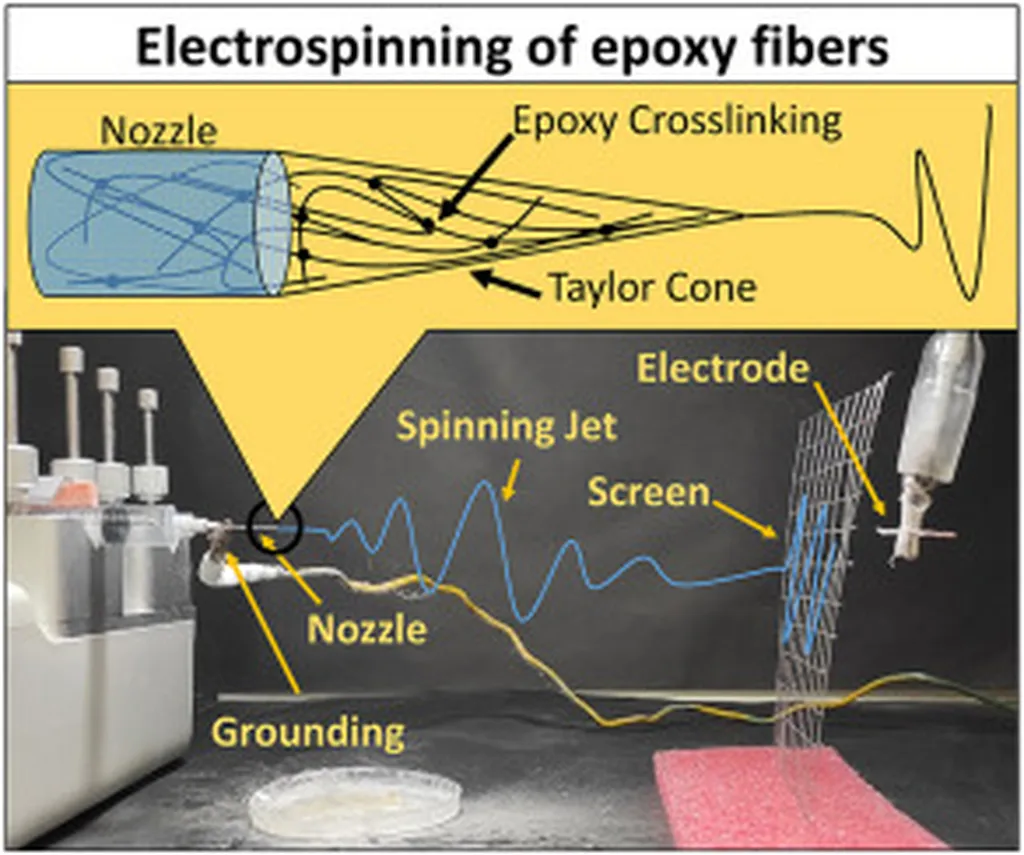

Electrospinning, a technique widely used for manufacturing nanofibers from polymers, has typically been limited to thermoplastics due to their chain entanglements. However, Shneider and his team have challenged this norm by demonstrating that thermosetting polymers like epoxy, known for their crosslinked covalent bonds, can also be electrospun. The resulting fibers, with diameters ranging from a mere 150 nanometers to 6 micrometers, exhibit remarkable mechanical properties.

“Our findings show that these electrospun epoxy fibers are not just stronger but also more ductile compared to their bulk counterparts,” Shneider explained. The fibers displayed approximately 555% higher strength, 300% greater stiffness, and a strain of about 109% compared to bulk epoxy. This ductility is a significant departure from the typically brittle nature of molded epoxy, opening new avenues for applications in high-performance materials.

The study also revealed a correlation between fiber diameter and mechanical properties, suggesting that size plays a crucial role in enhancing the performance of these materials. To understand these size effects better, the team employed polarized micro-Raman spectroscopy to analyze the molecular orientation and morphology of the fibers. This detailed analysis provided insights into the transition from brittle to ductile behavior in epoxy fibers, clarifying the molecular mechanisms behind their improved mechanical properties.

The implications of this research are vast, particularly for the energy sector. The enhanced strength and ductility of these epoxy fibers could lead to the development of more robust and flexible composite materials, which are essential for constructing durable and efficient energy infrastructure. From wind turbine blades to high-voltage insulation, the potential applications are numerous and could significantly impact the reliability and performance of energy systems.

Moreover, the ability to electrospun thermosetting polymers like epoxy could pave the way for innovative materials with tailored properties, meeting the specific demands of various industries. As Shneider noted, “This research not only advances our understanding of polymer behavior but also opens up new possibilities for designing materials with enhanced performance.”

The study’s findings, published in “Polymer Letters Express,” mark a significant step forward in the field of materials science. By pushing the boundaries of what is possible with electrospinning, Shneider and his team have set the stage for future developments that could transform the way we build and power our world. As the energy sector continues to evolve, the need for advanced materials that can withstand extreme conditions and deliver superior performance has never been greater. This research offers a promising path forward, highlighting the potential of electrospun epoxy fibers to meet these challenges head-on.