In the ever-evolving world of construction materials, a groundbreaking study led by Wenyi Yang from the School of Water Conservancy at Yunnan Agricultural University in Kunming, China, is set to revolutionize how we predict the compressive strength of cement-based composites. Published in *Engineering Reports* (translated to English as “Engineering Reports”), this research harnesses the power of machine learning to forecast the strength of cellulose nanofibrils (CNFs) reinforced concrete, cement paste, and cement mortar before construction even begins.

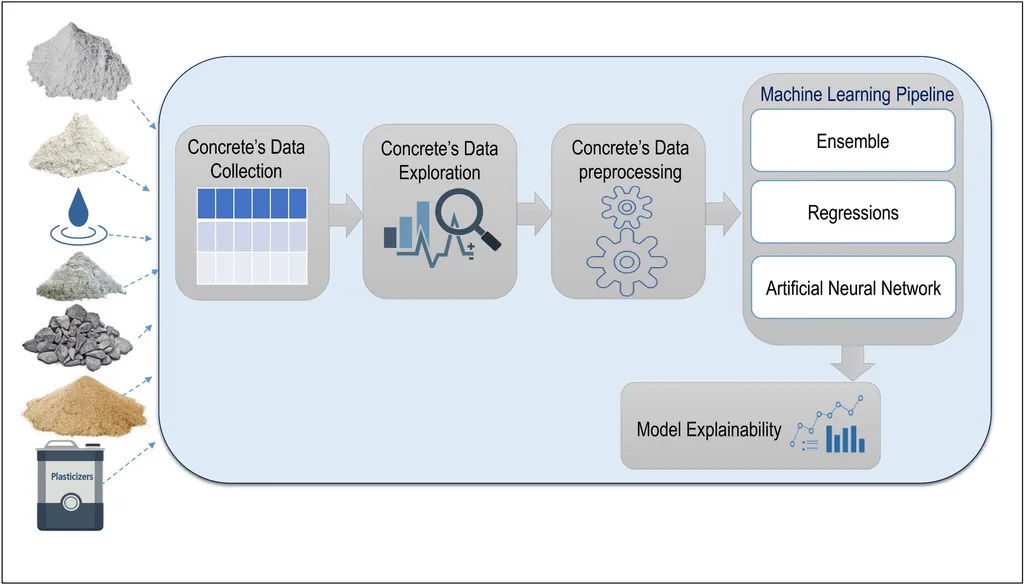

The study, which utilized ten supervised regression machine learning models, analyzed datasets comprising 266 data points for cement paste, 233 for cement mortar, and 196 for concrete. Each dataset included seven input parameters: cement, water, CNFs, superplasticizer, fine aggregate, coarse aggregate, and age, with the output parameter being compressive strength (fc). The results were impressive, with seven models for cement paste, six for cement mortar, and eight for concrete demonstrating a strong ability to predict compressive strength accurately.

“Our findings indicate that machine learning models can be highly effective in predicting the compressive strength of cement-based composites,” said Wenyi Yang. “This predictive capability can significantly enhance the efficiency and accuracy of construction projects, ultimately leading to cost savings and improved structural integrity.”

The sensitivity analysis revealed that water and cement were the parameters with the largest impacts on predicting the compressive strength of CNFs reinforced cement-based composites, while coarse aggregate had the smallest impact. This insight is crucial for optimizing the composition of construction materials to achieve desired strength properties.

The research identified the best prediction models for each material: Extreme Gradient Boosting Regression, Gradient Boosting Regression, and Random Forest for concrete; Extreme Gradient Boosting Regression, Gradient Boosting Regression, and Decision Tree for cement paste; and K-Nearest Neighbors, Bagging Regressor, and Random Forest for cement mortar.

The implications of this research are far-reaching, particularly for the energy sector. Accurate prediction of compressive strength can lead to the development of more durable and efficient construction materials, reducing the need for frequent repairs and replacements. This, in turn, can lower maintenance costs and improve the overall sustainability of energy infrastructure.

As the construction industry continues to embrace technological advancements, the integration of machine learning models into material science represents a significant step forward. The research conducted by Wenyi Yang and his team not only provides valuable insights into the predictive capabilities of these models but also paves the way for future innovations in the field.

In the words of Wenyi Yang, “This study opens up new possibilities for the construction industry, enabling us to build smarter, stronger, and more sustainable structures.” With the findings published in *Engineering Reports*, the stage is set for a new era of precision and efficiency in construction materials.