In the relentless battle against corrosion, researchers have made a significant stride in understanding the stability of pitting corrosion in stainless steel, a critical material in the energy sector. Dr. Wei Liu, a physicist from Ningxia Normal University in China, has led a study that could revolutionize how we predict and prevent corrosion-related failures in infrastructure.

Corrosion, particularly pitting corrosion, is a persistent challenge in the energy industry. It leads to costly repairs and potential safety hazards. Stainless steel, widely used in pipelines, storage tanks, and other critical infrastructure, is not immune to this process. Understanding when a pit becomes stable and starts to grow is crucial for predicting and preventing failures.

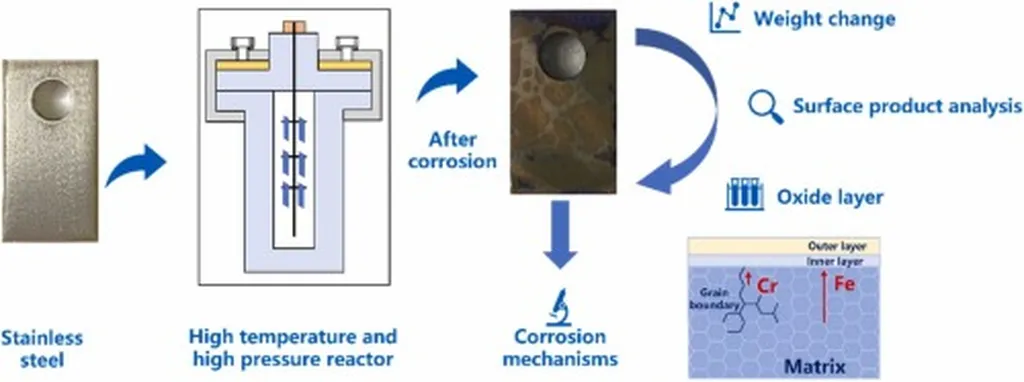

Dr. Liu’s research, published in the journal *Corrosion Communications* (translated from the original Chinese title), focuses on the electrochemical noise transient analysis, a method that monitors the tiny electrical signals generated during corrosion processes. “By analyzing these signals, we can gain insights into the dynamics of pitting corrosion,” Dr. Liu explains. The study introduces a novel approach to estimate the transition to stable pitting by examining the pitting current growth rate and its amplitude.

The research builds upon a theoretical framework proposed by Li, Scully, and Frankel, which emphasizes the importance of the pitting current density in maintaining a sustainable dynamic balance within the pit. Dr. Liu’s work introduces a quantitative indicator that aligns with this framework, providing a more precise method for estimating the onset of stable pitting.

The implications for the energy sector are substantial. By better predicting when pitting corrosion will become stable and start to grow, engineers can implement more effective maintenance strategies. This could lead to significant cost savings by reducing unplanned downtime and extending the lifespan of critical infrastructure.

Moreover, this research could pave the way for the development of new materials and coatings designed to resist pitting corrosion more effectively. As Dr. Liu notes, “Our findings could guide the development of next-generation materials with improved corrosion resistance, benefiting various industries beyond energy, such as construction and manufacturing.”

The study also highlights the importance of advanced analytical techniques in corrosion research. By leveraging electrochemical noise transient analysis, researchers can gain deeper insights into the complex processes underlying corrosion. This could lead to further breakthroughs in understanding and mitigating corrosion-related issues.

In an industry where safety and reliability are paramount, Dr. Liu’s research offers a promising avenue for enhancing the performance and longevity of stainless steel infrastructure. As the energy sector continues to evolve, the need for robust and corrosion-resistant materials will only grow. This study provides a crucial step forward in meeting that need.

Dr. Liu’s work not only advances our scientific understanding but also offers practical solutions that could have a significant impact on the energy sector. By bridging the gap between theoretical research and real-world applications, this study exemplifies the potential of interdisciplinary collaboration in addressing critical industrial challenges.