In a significant stride towards sustainable manufacturing, researchers have demonstrated that hot extrusion and heat treatment can substantially enhance the mechanical properties of recycled aluminum composites. The study, led by Amin Shah Omar of the Sustainable Manufacturing and Recycling Technology division at Universiti Tun Hussein Onn Malaysia, focuses on AA6061 aluminum chips reinforced with rice husk ash (RHA), a byproduct of rice processing. The findings, published in *AIMS Materials Science* (which translates to *Journal of Materials Science*), offer promising avenues for the energy sector and beyond.

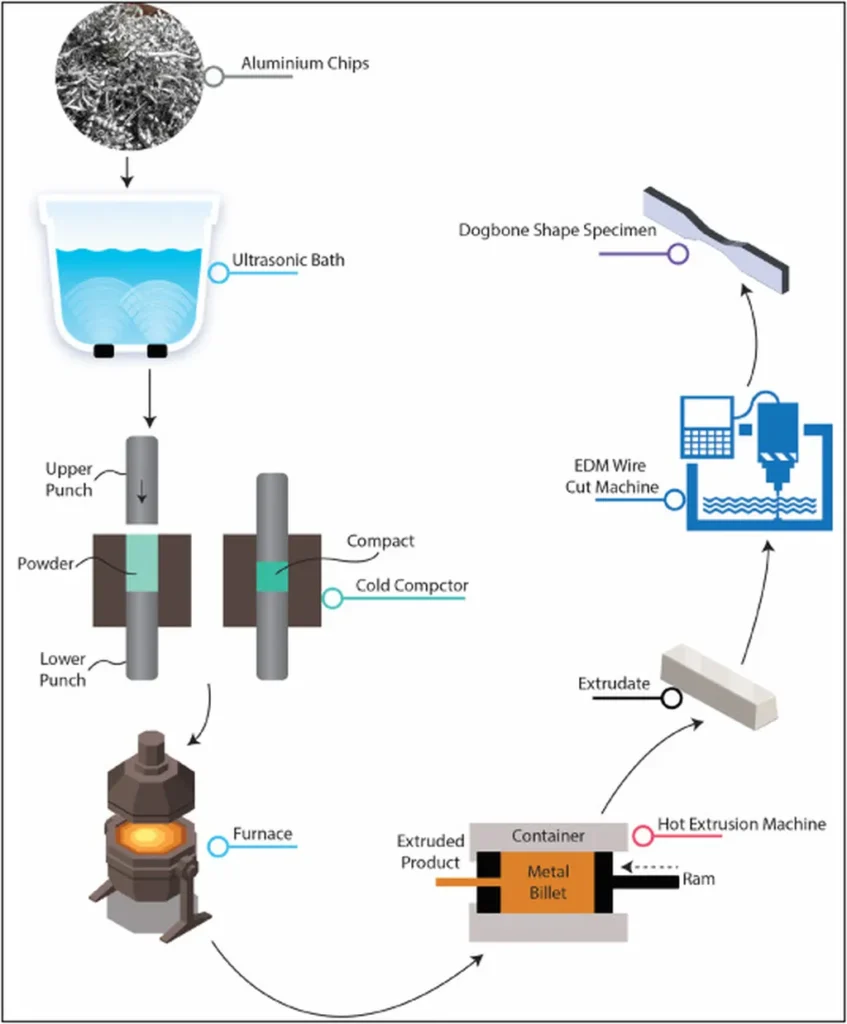

The direct recycling method employed in this research is gaining traction for its potential to reduce waste and costs while being environmentally friendly. Omar and his team investigated the effects of these processes on the fatigue life and other mechanical properties of the composite material. The cold compacted billets were preheated and extruded, with half undergoing a subsequent heat treatment process.

The results were striking. The heat-treated samples exhibited the highest ultimate tensile strength (UTS) of 145.65 MPa, a hardness of 64.78 HV, and a density of 2.64 g/cm³. “The heat treatment process significantly improved the microstructure and mechanical properties of the composite,” Omar noted. This enhancement in properties is crucial for applications requiring high strength and durability, such as those in the energy sector.

The study also revealed that heat-treated samples had a higher fatigue limit compared to non-treated ones. Using Basquin’s equation, the researchers were able to predict the fatigue life of the composite at untested stress amplitudes, providing valuable data for practical applications. Energy dispersive spectroscopy (EDS) analysis showed that the treated samples were composed mainly of aluminum, with significant amounts of magnesium and oxygen. Atomic force microscopy (AFM) analysis indicated that the grain length of the heat-treated samples ranged from 0.792 to 0.894 µm, larger than that of the untreated samples.

The implications of this research are far-reaching. By improving the mechanical properties of recycled aluminum composites, the study paves the way for more sustainable and cost-effective materials in various industries. “This research highlights the potential of direct recycling methods and heat treatment processes in enhancing the performance of composite materials,” Omar explained. The energy sector, in particular, stands to benefit from these advancements, as the demand for durable and high-strength materials continues to grow.

As the world moves towards more sustainable practices, the findings of this study offer a glimpse into the future of materials science. The enhanced properties of the recycled aluminum composites could lead to more efficient and environmentally friendly solutions in construction, transportation, and energy production. With further research and development, these materials could become a cornerstone of sustainable manufacturing, shaping the future of the energy sector and beyond.