In the quest for sustainable construction materials, a recent study published in the journal *AIMS Materials Science* (translated from Chinese as “Materials Science”) has shed new light on the performance of Portland cement pastes when inert limestone fillers (ILSF) are used to replace clinker content. The research, led by Andrés A. Torres-Acosta from the Tecnologico de Monterrey, School of Engineering and Science, Department of Sustainable Technologies and Civil, challenges the industry’s traditional understanding of clinker replacement levels.

Torres-Acosta and his team evaluated six different blended Portland cements (BPCs) from two brands, with loss of ignition (LOI) values ranging from 2% to 18%, corresponding to ILSF contents between 5% and 35%. The study is particularly significant because, as Torres-Acosta notes, “marginal information is available in the literature regarding the performance of Portland cement–based pastes when reducing clinker content with inert limestone fillers when the replacement is greater than 15%.”

The researchers conducted a series of laboratory tests to characterize the BPCs, including determining fineness, density, and LOI. They then performed paste characterization tests, such as water content for normal consistency, setting times, luminosity coordinate of hardened paste specimens, and mortar compressive strength at 28 days. The findings suggest that obtaining the LOI parameter can help forecast the performance of new BPC formulations, even when the exact composition of the cement is unknown due to trademark secrecy.

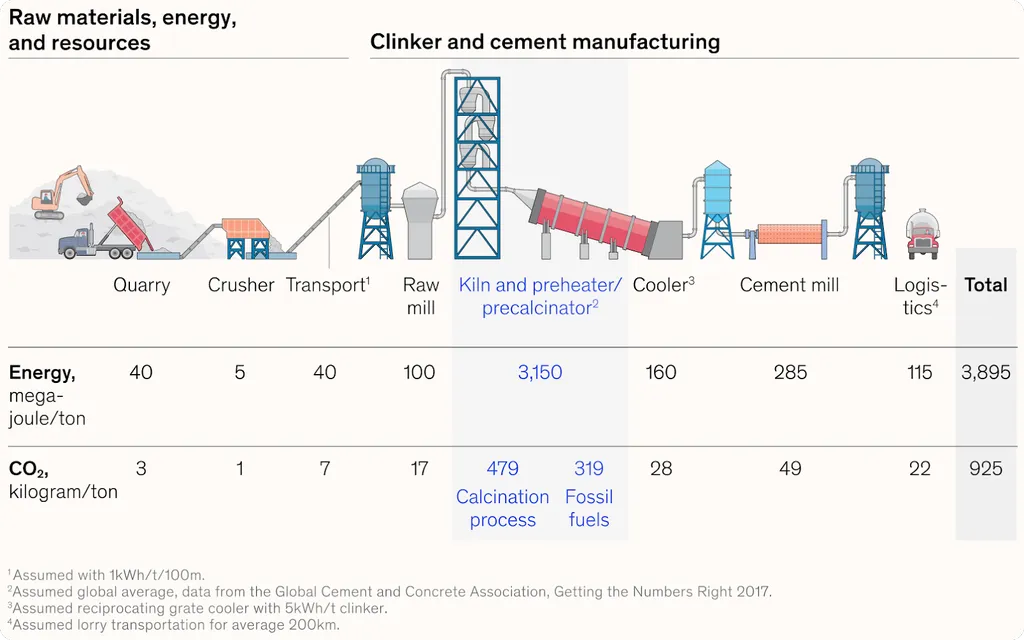

This research has significant implications for the energy sector, particularly in the production of cement, which is a major contributor to global CO2 emissions. By optimizing the use of ILSF, the industry could reduce its reliance on clinker, a key source of emissions. “One way to overcome the misinformation about the composition of BPCs is to obtain the LOI parameter,” Torres-Acosta explains, highlighting the potential for this approach to drive innovation in sustainable construction materials.

The study also opens up new avenues for future research. As the construction industry continues to seek ways to reduce its environmental impact, understanding the performance of BPCs with high levels of ILSF could pave the way for more sustainable and energy-efficient building materials. The findings from this research could influence industry standards and practices, encouraging manufacturers to explore new formulations that balance performance and sustainability.

In conclusion, this study is a significant step forward in the quest for sustainable construction materials. By providing a deeper understanding of the performance of Portland cement pastes with high levels of ILSF, it offers valuable insights for the energy sector and the construction industry as a whole. As Torres-Acosta’s research demonstrates, there is still much to learn about the potential of these materials, and the journey towards more sustainable construction is far from over.