In a groundbreaking development for the construction and energy sectors, researchers have optimized the friction stir welding (FSW) process for aluminum metal matrix composites (AMMCs) reinforced with zirconium dioxide (ZrO2) particles. This advancement, led by Umar Mohamed Jamaludeen, promises to enhance the mechanical properties of these composites, paving the way for more robust and efficient applications in various industries.

Aluminum alloys, particularly AA6092, are widely used for their excellent mechanical properties and customizable thermal and electrical characteristics. The incorporation of ZrO2 particles further enhances these properties, making the composites suitable for high-stress applications such as engine valve seats, fuel cell membranes, and electronic equipment. However, traditional welding methods often compromise these properties, leading to defects and reduced performance.

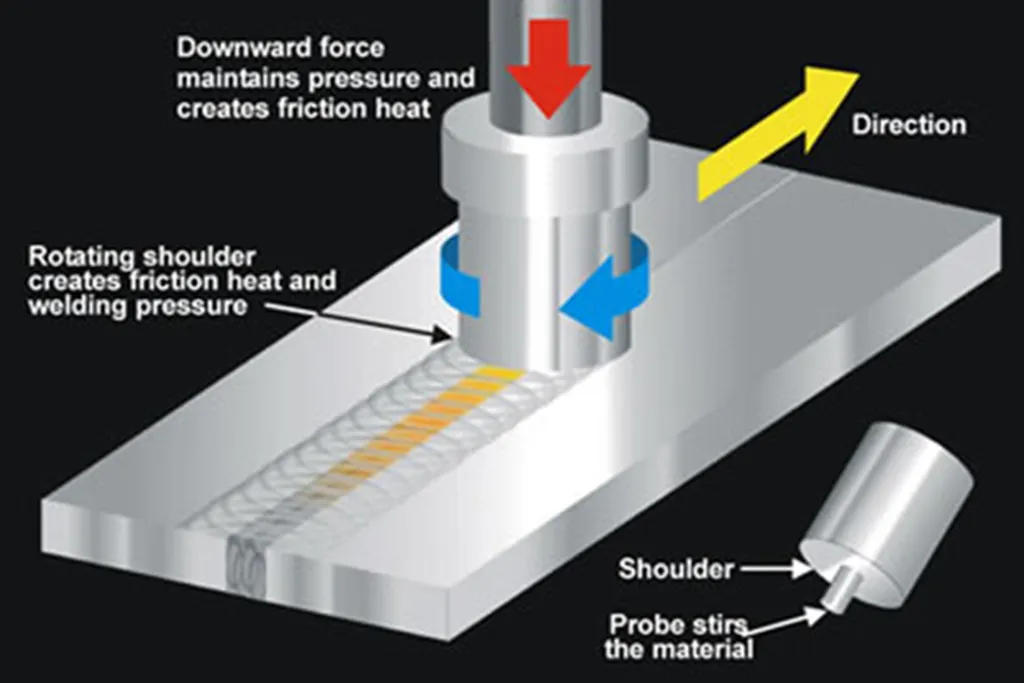

Enter friction stir welding, a solid-state joining technique that effectively preserves the mechanical properties of AMMCs. “FSW is a game-changer for AMMCs,” says Jamaludeen. “It allows us to join these materials without the defects commonly associated with traditional fusion welding methods.”

In their study published in ‘Materials Research’ (translated to English as ‘Pesquisa em Materiais’), Jamaludeen and his team developed regression models to predict the ultimate tensile strength (UTS), percent elongation (PE), and weld nugget hardness (WNH) of friction stir welded AA6092 composites reinforced with ZrO2 particles. The models correlate these mechanical properties with key FSW parameters, including tool rotational speed, welding speed, axial load, and the percentage of ZrO2 reinforcement.

Using response surface methodology and analysis of variance (ANOVA), the team identified optimized welding conditions: a tool rotational speed of 1208.09 rpm, a welding speed of 51.5 mm/min, an axial load of 5.13 kN, and 15 wt.% ZrO2 reinforcement. Under these parameters, the composites achieved impressive mechanical properties, with a UTS of 494.81 MPa, a PE of 8.51%, and a WNH of 184.57 HRB.

The developed regression models demonstrated high accuracy, with prediction errors below ±5% for all responses. “These models are not just accurate; they are practical,” Jamaludeen explains. “They allow us to predict the mechanical properties of these composites under various welding conditions, enabling us to tailor the process to specific applications.”

The implications of this research are significant for the energy sector, where the demand for lightweight, high-strength materials is growing. The optimized FSW process could lead to the development of more efficient and durable components for energy generation and transmission, as well as for energy storage systems.

Moreover, the study’s findings could shape future developments in the field of advanced manufacturing. By providing a reliable method for joining AMMCs, the research opens up new possibilities for designing and fabricating complex structures with enhanced mechanical properties.

As the world continues to seek sustainable and efficient solutions for energy production and use, the optimized FSW process for AA6092/ZrO2 composites offers a promising path forward. With further research and development, this technology could play a crucial role in shaping the future of the energy sector and beyond.