In the quest for sustainable packaging solutions, a recent study published in the journal *Materials Research* (translated from Portuguese) has uncovered promising advancements in the realm of biodegradable polymers. Led by N. B. Agostini, the research delves into the optimization of PLA/PBAT blends, a combination of polylactic acid (PLA) and polybutylene adipate-co-terephthalate (PBAT), through the addition of various organic additives. The findings could significantly impact the packaging industry’s shift towards more eco-friendly materials.

The study, conducted by Agostini and their team, explored the effects of five different additives—citric acid, lauric acid, gum rosin, cellulose nanocrystals, and poly(vinyl acetate) (PVAc)—on the thermal, mechanical, rheological, and microstructural properties of PLA/PBAT blends. The goal was to enhance these blends’ performance, making them more viable for widespread use in biodegradable packaging.

Among the additives tested, PVAc emerged as the standout performer. “PVAc showed the most promising results, improving phase dispersion through a core-shell structure and enhancing tensile strength by 11.9%, toughness by 32%, and flexural stress by 26.5%,” Agostini explained. This improvement in mechanical properties is a significant step forward, as it addresses one of the primary challenges in the adoption of biodegradable polymers: their often-inferior performance compared to traditional petroleum-based plastics.

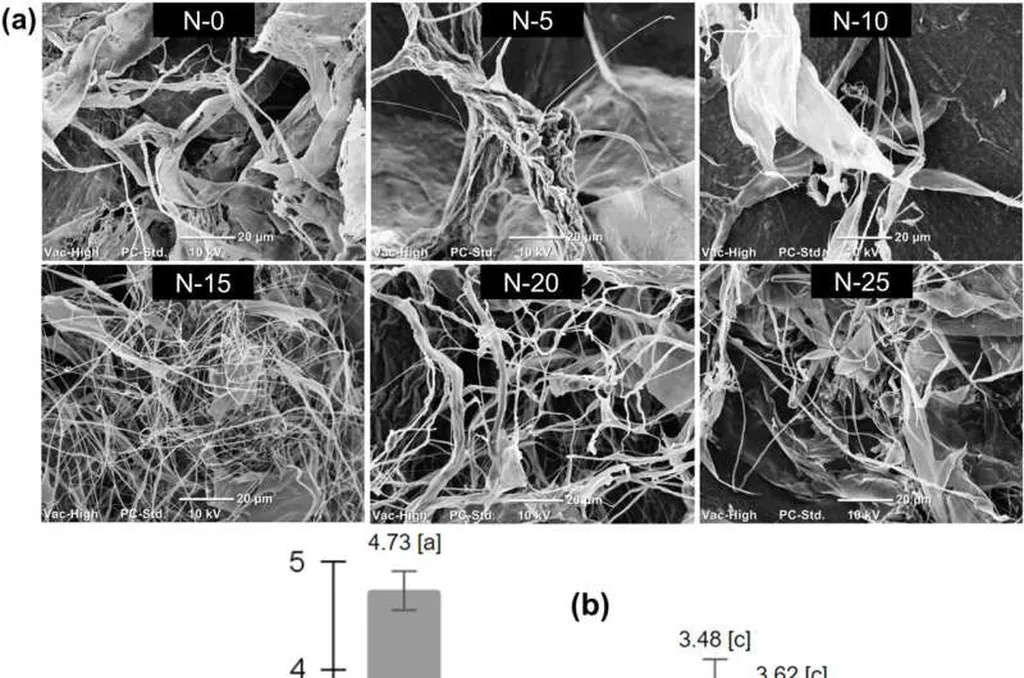

The research involved a meticulous process of blending the materials in an internal mixing chamber and then subjecting them to injection molding for mechanical testing. The team conducted a comprehensive suite of characterizations, including tensile, flexural, and Izod impact tests, as well as thermal analyses like differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA). Rheological assessments and scanning electron microscopy (SEM) were also employed to gain a holistic understanding of the blends’ properties.

The implications of this research are far-reaching for the packaging industry and beyond. As the demand for sustainable materials grows, driven by both regulatory pressures and consumer preferences, the development of high-performance biodegradable polymers becomes increasingly critical. Agostini’s work provides valuable insights into how these materials can be optimized to meet the rigorous demands of various applications.

“Our findings highlight the potential of PVAc as an additive to enhance the performance of PLA/PBAT blends,” Agostini noted. “This could pave the way for more sustainable packaging solutions that do not compromise on quality or functionality.”

The study not only contributes to the scientific understanding of polymer blends but also offers practical guidance for industry stakeholders looking to adopt more sustainable materials. By demonstrating the effectiveness of PVAc in improving the mechanical properties of PLA/PBAT blends, the research opens up new possibilities for the development of biodegradable packaging that can compete with traditional plastics in terms of performance.

As the world continues to grapple with the environmental impact of plastic waste, innovations in biodegradable materials are more important than ever. Agostini’s research, published in *Materials Research*, represents a significant step forward in this endeavor, offering a glimpse into a future where sustainable packaging is not just an ideal but a reality. The findings could shape future developments in the field, driving the industry towards more eco-friendly and efficient solutions.