In the relentless battle against concrete deterioration, researchers have turned to an unlikely ally: X-ray fluorescence (XRF). A recent study published in ‘Materials Research’ (or ‘Pesquisa em Materiais’ in English) has shed light on how this technique can help evaluate chloride ion penetration in concrete, a critical factor in the longevity of reinforced concrete structures. The research, led by Ramon Santos Souza, offers promising insights for the construction and energy sectors, where the integrity of concrete structures is paramount.

Chloride ions are the stealthy adversaries that infiltrate concrete through its porous network, leading to the corrosion of steel reinforcement. This process not only compromises structural integrity but also incurs substantial repair costs. The study employed two accelerated methods, ASTM C1202 and NT Build 492, to hasten chloride ion migration and evaluate the effectiveness of different cement types in hindering this progression.

The findings revealed that cements containing slag and pozzolan exhibited high resistance to chloride penetration. “These materials modify the cementitious matrix in a way that significantly slows down the advancement of chloride ions,” explained Souza. On the other hand, cements with filler showed lower resistance, highlighting the importance of careful material selection in concrete production.

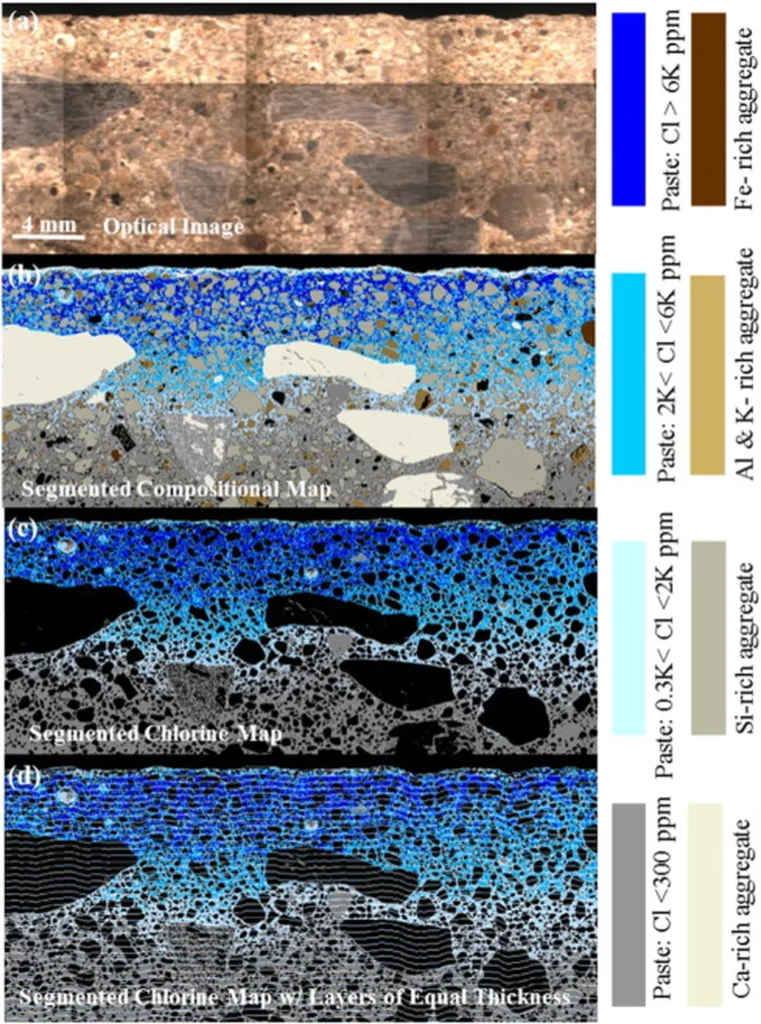

The XRF technique played a pivotal role in this research. By identifying the elements present in a sample and creating intensity distribution maps, XRF provided a detailed understanding of chloride penetration. This technique’s non-destructive nature and ability to offer real-time data make it an invaluable tool for quality control and research in the construction industry.

The commercial implications of this research are substantial, particularly for the energy sector. Offshore wind farms, coastal power plants, and other energy infrastructure often face harsh environmental conditions that accelerate concrete degradation. By adopting cements with high resistance to chloride penetration, energy companies can enhance the durability of their structures, reduce maintenance costs, and ensure the safety and reliability of their operations.

Moreover, the insights gained from this study could shape future developments in cement technology. As Souza noted, “Understanding how different cement types interact with chloride ions can guide the development of more resilient and sustainable construction materials.” This could lead to innovations in cement formulation, ultimately benefiting the entire construction industry.

In conclusion, the research led by Ramon Santos Souza represents a significant step forward in the fight against concrete deterioration. By leveraging the power of XRF and exploring the potential of different cement types, the study offers valuable insights for the construction and energy sectors. As the industry continues to grapple with the challenges of durability and sustainability, this research provides a beacon of hope and a roadmap for future developments.