In the quest for sustainable construction materials, a team of researchers led by Dongtao Xia from the School of Civil Engineering, Architecture and Environment at Hubei University of Technology in China has made a significant breakthrough. Their study, published in the journal *Materials Research Express* (which translates to “Materials Research Express” in English), explores the potential of waterborne epoxy resin (WER) to enhance the mechanical properties and microstructures of geopolymeric recycled aggregate concrete (GRAC). This research could have profound implications for the energy sector, particularly in the construction of low-carbon, durable infrastructure.

GRAC has long been touted as an eco-friendly alternative to traditional concrete, thanks to its superior performance and reduced environmental impact. However, its practical application has been hindered by issues of toughness and brittleness. Xia and his team set out to address these challenges by incorporating WER into the mix. “We aimed to mitigate the adverse effects of recycled aggregate (RA) substitution and improve the overall mechanical properties of GRAC,” Xia explains.

The researchers conducted a series of experiments, varying the content of WER and RA to assess their impact on setting time, mechanical strengths, stress-strain response, and microstructure. The results were promising. While an increase in RA content generally led to a deterioration in mechanical performance, the addition of WER effectively counteracted this effect. “The incorporation of WER enhanced the splitting tensile and flexural strengths of GRAC, leading to a growth in compressive toughness and improved ductility,” Xia notes.

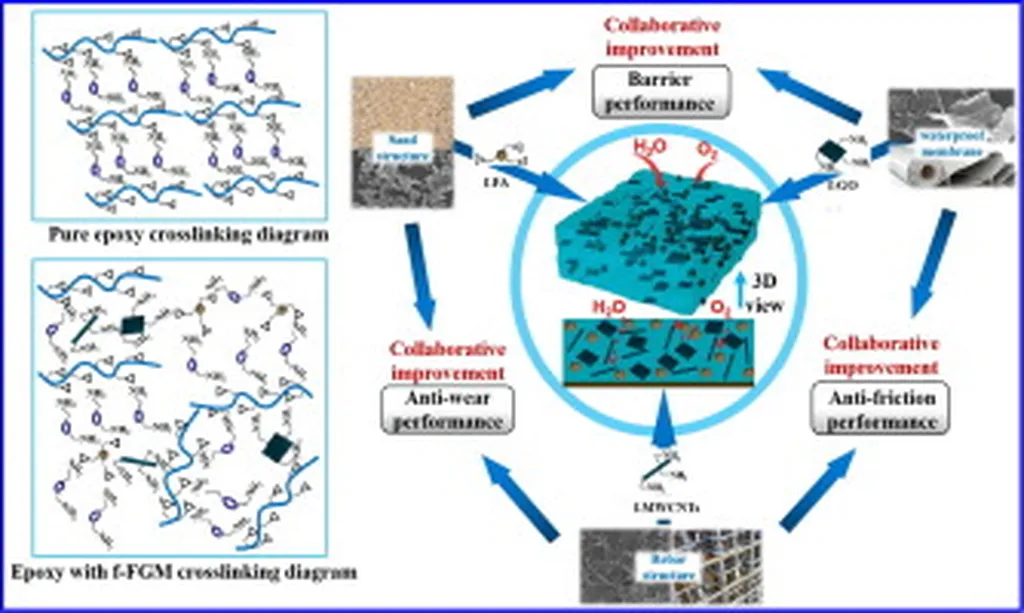

The study also revealed that WER interacts with C-A-S-H (calcium-alumino-silicate-hydrate) to form a compact organic-inorganic interpenetrating network structure, strengthening the GRAC matrix. Furthermore, the addition of 4% WER content reduced the total porosity of GRAC by 31.2% compared to GRAC without WER. These findings suggest that WER could play a crucial role in enhancing the durability and longevity of GRAC structures.

One of the most significant aspects of this research is its potential to shape future developments in the field of sustainable construction. By improving the mechanical properties of GRAC, WER could pave the way for its wider adoption in the construction of low-carbon, energy-efficient buildings and infrastructure. This, in turn, could have a substantial impact on the energy sector, reducing the carbon footprint of construction projects and contributing to global sustainability goals.

The study also presents a refined stress-strain model to depict the compressive stress-strain curve of GRAC, considering differing dosages of RA and WER. This model could serve as a valuable tool for engineers and researchers seeking to optimize the performance of GRAC in practical applications.

In addition to its technical contributions, the research also highlights the superior environmental performance of GRAC compared to ordinary concrete. Life Cycle Assessment (LCA) results demonstrate that GRAC is a low-carbon material, making it an attractive option for environmentally conscious construction projects.

As the world grapples with the challenges of climate change and resource depletion, the development of sustainable construction materials has become more critical than ever. The research led by Dongtao Xia offers a glimmer of hope, demonstrating the potential of WER to enhance the properties of GRAC and contribute to the construction of a more sustainable future. With further research and development, this innovative approach could revolutionize the construction industry and pave the way for a greener, more energy-efficient world.