In a groundbreaking development that could revolutionize bone tissue engineering, researchers have successfully created a biological bone scaffold using a novel decellularization method. This innovative approach, detailed in a study led by Aylin Kara Özenler from the Department of Bioengineering at Izmir Institute of Technology, preserves the intricate structure of bone extracellular matrix (ECM) while effectively removing cellular components. The findings, published in the journal Exploration of BioMat-X (translated as “Exploration of Biomaterials”), open new avenues for bone regeneration and tissue engineering.

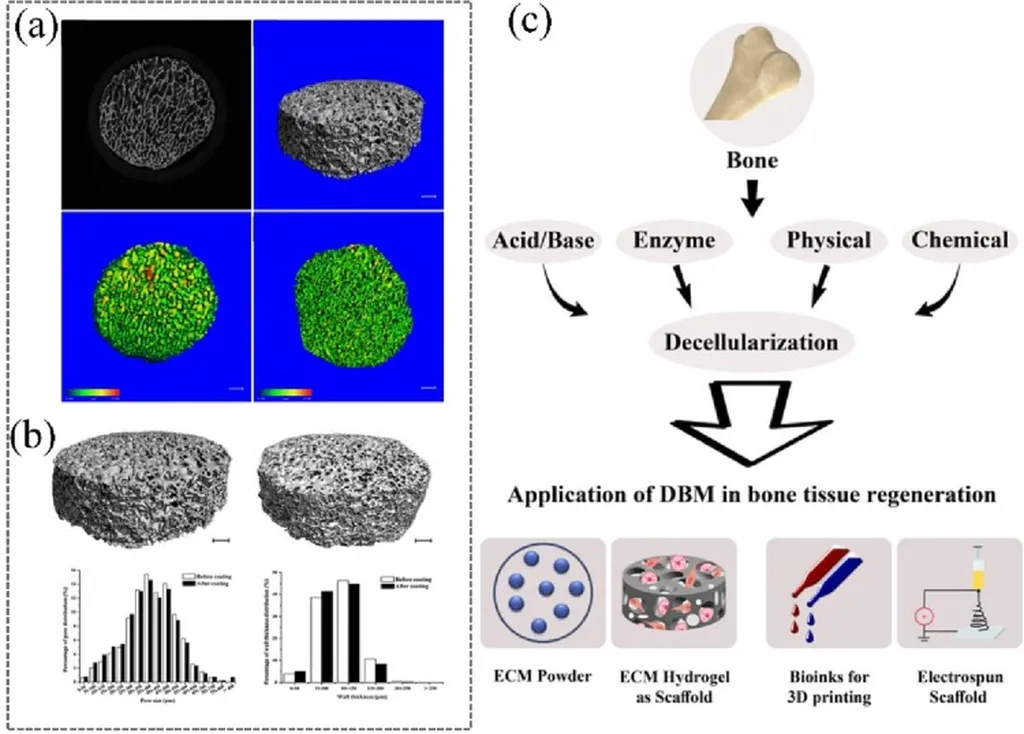

The study focuses on developing a biological bone ECM using a combination of physical, chemical, and enzymatic methods with a minimal concentration of sodium dodecyl sulfate (SDS). This method ensures that both organic and inorganic compounds of the bone are preserved, maintaining the biomechanical and biochemical properties essential for bone regeneration.

“Our method effectively removes cellular components while preserving the ultrastructural composition of the ECM,” explained Özenler. “This is crucial for creating a biocompatible and bioactive environment that supports cell growth and bone regeneration.”

The researchers achieved a significant reduction in DNA content, with 95% for rabbit bone and 92% for rat bone, indicating successful decellularization. Importantly, the mineralization features of the bone were preserved, ensuring that the decellularized bone substitutes could effectively support new bone growth.

One of the most compelling aspects of this research is its potential impact on the medical and construction industries. In the medical field, the development of biological bone substitutes could transform orthopedic surgeries and treatments for bone diseases. For the construction industry, understanding and utilizing bone ECM could lead to the development of stronger, more durable materials inspired by natural structures.

“The decellularized bone extracellular matrix (dbECM) provides a suitable environment for cell growth, making it a promising substrate for bone tissue engineering,” said Özenler. “This could lead to significant advancements in regenerative medicine and the development of new biomaterials.”

The study’s findings also highlight the importance of minimizing chemical concentration and incubation time during the decellularization process. This not only reduces potential cytotoxic effects but also makes the process more efficient and cost-effective.

As the construction industry continues to seek innovative solutions for sustainable and durable materials, the insights gained from this research could inspire new approaches to material science. By understanding the natural processes of bone regeneration, researchers and engineers may develop materials that mimic the strength and resilience of bone, leading to more robust and eco-friendly construction materials.

In conclusion, the research led by Aylin Kara Özenler represents a significant step forward in the field of bone tissue engineering. The novel decellularization method offers a promising approach to creating biological bone substitutes that could transform medical treatments and inspire new developments in the construction industry. As the findings are further explored and applied, the potential for advancements in regenerative medicine and material science is immense, paving the way for a future where natural and synthetic materials converge to create innovative solutions.