In a groundbreaking study published in the journal *Materials Today Advances* (which translates to *Advances in Materials Today*), researchers have uncovered new insights into the formation of hierarchical microstructures in copper-iron (Cu-Fe) immiscible alloys. This research, led by S. Sarmast-Ghahfarokhi from the Department of Mechanical and Mechatronics Engineering at the University of Waterloo, Canada, could pave the way for enhanced mechanical properties in alloys used across various industries, particularly in the energy sector.

Cu-Fe alloys are known for their potential to form complex microstructures under rapid solidification conditions, but the processes driving these formations during melting and mixing have remained a mystery. Sarmast-Ghahfarokhi and his team set out to change that. “Understanding the microstructural evolution in Cu-Fe alloys is crucial for tailoring their mechanical properties,” Sarmast-Ghahfarokhi explained. “Our study provides a foundation for optimizing these alloys for advanced engineering applications.”

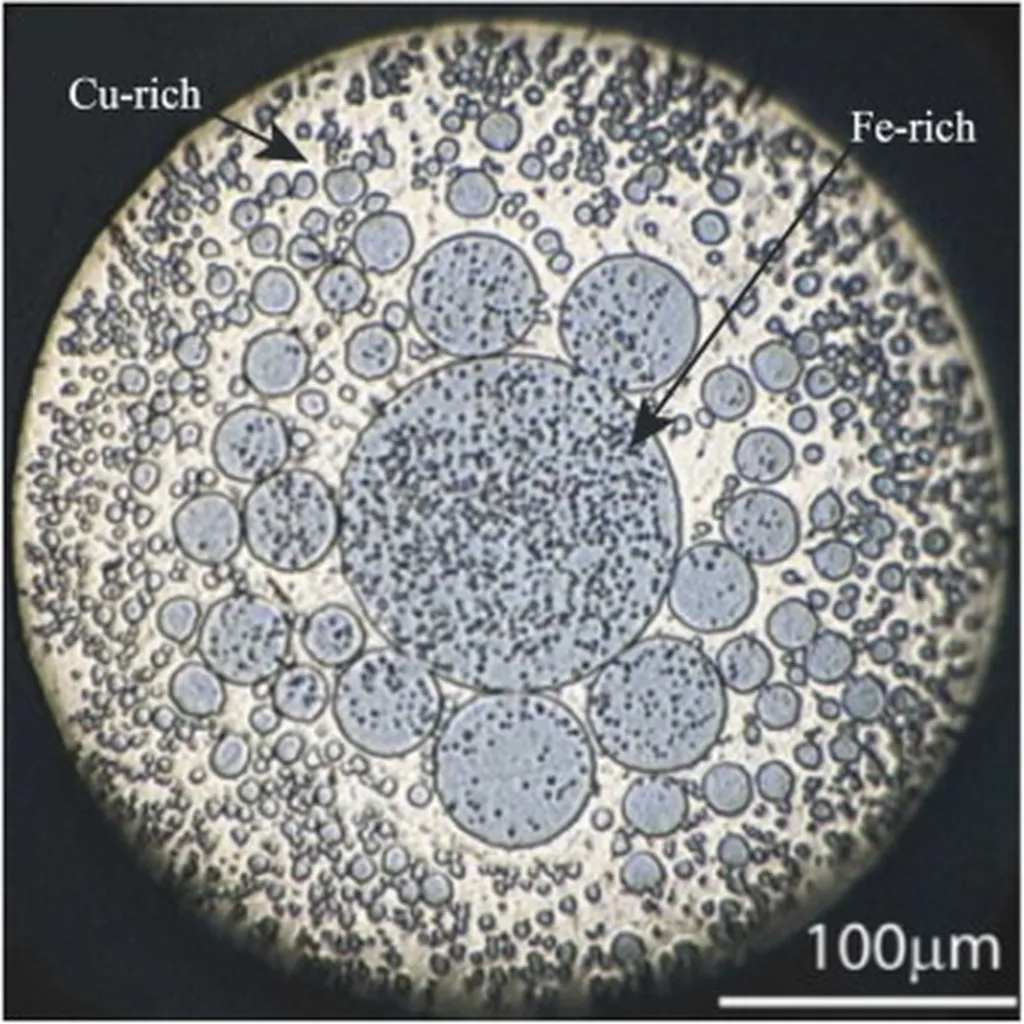

The researchers found that the formation of hierarchical microstructures in Cu-Fe alloys is governed by two distinct regimes, depending on the degree of iron (Fe) dilution. In high-Fe content samples, phase separation during the liquid state, followed by Marangoni-driven motion, led to the creation of a hierarchical structure. This structure includes DO3-ordered Fe-rich particles with embedded Cu-rich grains and uniformly distributed L12 nanoparticles. In contrast, low-Fe samples exhibited more uniformly dispersed, smaller DO3-ordered Fe-rich particles with a lower number density, along with dispersed L12 nanoprecipitates.

These microstructures, driven by surface energy mechanisms and solute trapping under rapid cooling, significantly enhance the local hardness and elastic modulus of the alloys. “The increased number density of Fe-rich particles plays a dominant role in strengthening Cu-Fe alloys,” Sarmast-Ghahfarokhi noted. This finding highlights the importance of microstructural tailoring in improving the mechanical performance of these alloys.

The implications of this research are far-reaching, particularly for the energy sector. Cu-Fe alloys with enhanced mechanical properties could be used in a variety of applications, from power generation to renewable energy technologies. By understanding and controlling the microstructural evolution of these alloys, engineers can develop materials that are stronger, more durable, and better suited to the demanding conditions of modern energy systems.

“This study offers a new perspective on the microstructural evolution of immiscible alloy systems,” Sarmast-Ghahfarokhi said. “It provides a roadmap for future research and development in this field, with the potential to revolutionize the way we design and use these materials.”

As the energy sector continues to evolve, the need for advanced materials that can withstand extreme conditions and deliver superior performance has never been greater. The insights gained from this research could shape the future of alloy development, opening up new possibilities for innovation and progress in the energy industry and beyond.