In the realm of industrial maintenance, particularly within the energy sector, the timely and accurate diagnosis of faults in critical machinery can mean the difference between smooth operations and costly downtime. A recent breakthrough in this field, published in the journal *Jixie qiangdu* (which translates to *Mechanical Strength*), promises to revolutionize fault diagnosis for three-phase induction motor bearings. The research, led by LIU Chao, introduces a novel diffusion-convolutional neural network (DCNN) model that addresses the perennial challenge of data scarcity in fault diagnosis.

Three-phase induction motors are the workhorses of many industrial applications, from power plants to manufacturing facilities. Their bearings are particularly susceptible to wear and tear, and early detection of faults can prevent catastrophic failures. However, the scarcity of actual fault samples has historically hindered the effectiveness of neural network models in diagnosing these issues. LIU Chao’s research tackles this problem head-on by combining the strengths of the denoising diffusion probabilistic model (DDPM) and convolutional neural networks (CNNs).

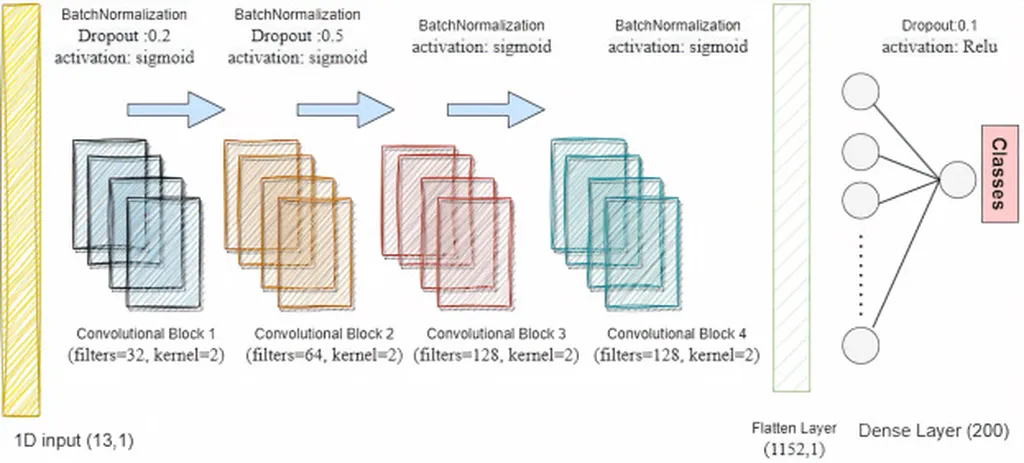

The DCNN model transforms raw vibration signals into two-dimensional time-frequency images using the Gramian angular difference field (GADF), enhancing the representational capacity of data features. This transformation allows the model to capture more nuanced information from the signals. “By converting the raw data into a more informative format, we can better train our models to recognize complex fault characteristics,” explains LIU Chao.

One of the most innovative aspects of the DCNN model is its use of a DDPM generator network to simulate the distribution of actual fault data. This synthetic data augmentation significantly expands the training dataset, enabling the model to achieve a diagnostic accuracy of 99.95%. “The ability to generate high-quality synthetic samples is a game-changer,” says LIU Chao. “It allows us to overcome the limitations of small-sample datasets and improve the robustness of our diagnostic models.”

The DCNN model also incorporates an improved U-Net architecture as its core denoising module, further enhancing its capability to recognize complex fault characteristics. The use of Wasserstein distance to minimize the discrepancy between generated and real data, along with spectral normalization to enhance model stability, ensures that the model remains accurate and reliable.

The implications of this research for the energy sector are profound. Accurate and timely fault diagnosis can lead to significant cost savings by reducing unplanned downtime and extending the lifespan of critical machinery. “This technology has the potential to transform maintenance strategies in the energy sector,” says LIU Chao. “By enabling early detection of faults, we can prevent costly breakdowns and improve overall operational efficiency.”

As the energy sector continues to evolve, the demand for advanced diagnostic tools will only grow. The DCNN model developed by LIU Chao and his team represents a significant step forward in this field. By addressing the challenge of data scarcity and improving diagnostic accuracy, this research paves the way for more reliable and efficient industrial operations.

Published in *Jixie qiangdu*, this groundbreaking study not only advances the field of fault diagnosis but also underscores the importance of innovative research in driving technological progress. As the energy sector continues to seek ways to optimize its operations, the insights gained from this research will be invaluable in shaping future developments.