In the rapidly evolving energy sector, the demand for lithium has surged, driven by the global push towards electric vehicles and renewable energy storage solutions. As the industry scrambles to meet this demand, researchers are exploring innovative strategies to extract and purify lithium more efficiently and sustainably. A recent review published in the journal *npj Materials Sustainability* (translated from Chinese as “Nature Journal of Materials Sustainability”) sheds light on the current state of lithium resources and novel extraction methods, offering a glimpse into the future of lithium production.

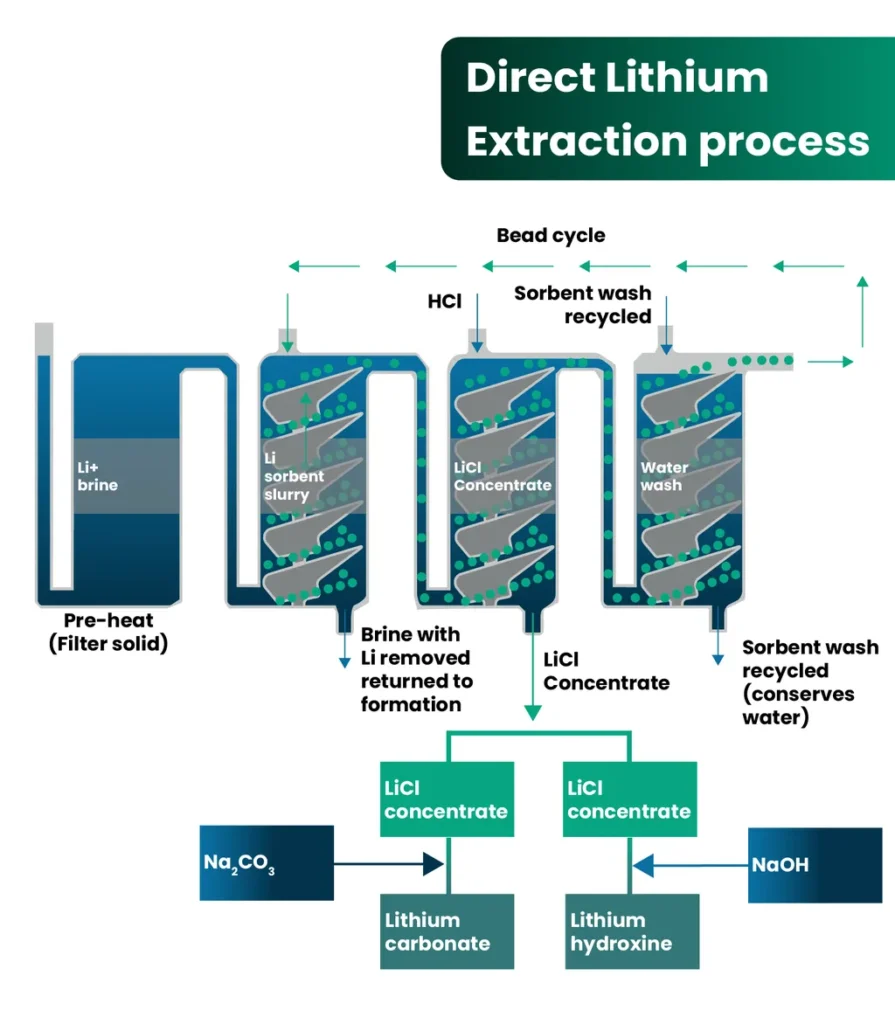

The review, led by Fangshuai Wu from the Department of Earth and Atmospheric Sciences at the University of Alberta, delves into the various sources of lithium, including igneous rocks, clays, and brines. It also examines traditional production methods and the recycling of lithium from spent batteries. However, the most compelling aspect of the research is its focus on direct lithium extraction (DLE) techniques, particularly those involving lithium manganese oxides (LMOs).

“Direct lithium extraction is a game-changer,” says Wu. “It allows us to bypass many of the environmental and economic challenges associated with traditional methods. By focusing on LMOs, we can potentially develop more efficient and sustainable processes for lithium production.”

One of the significant challenges in using LMOs for lithium extraction is sorbent degradation, which can hinder the performance and longevity of these materials. To address this issue, the review explores strategies such as doping, surface coating, and the use of composites. These innovations aim to enhance the performance of LMOs, making them more viable for large-scale lithium production.

The implications of this research for the energy sector are profound. As the demand for lithium continues to grow, the development of more efficient and sustainable extraction methods will be crucial. Direct lithium extraction techniques, particularly those involving LMOs, could revolutionize the industry, reducing costs and environmental impact while increasing supply.

“Our goal is to contribute to the development of a more sustainable and efficient lithium supply chain,” Wu explains. “By improving the performance of LMOs, we can help meet the growing demand for lithium in a way that is both economically viable and environmentally responsible.”

The review published in *npj Materials Sustainability* offers a comprehensive overview of the current state of lithium resources and extraction methods, highlighting the potential of direct lithium extraction techniques. As the energy sector continues to evolve, the innovations discussed in this research could play a pivotal role in shaping the future of lithium production.