In a groundbreaking development that could reshape the future of surface modification in the energy sector, researchers have uncovered new possibilities for expanded austenite, a highly durable and corrosion-resistant phase of metal alloys. This innovation, detailed in a recent study published in *MetalMat* (translated from Italian as *MetalMat*), opens doors for enhanced performance in austenitic stainless steels, nickel and cobalt alloys, and even the cutting-edge high-entropy alloys.

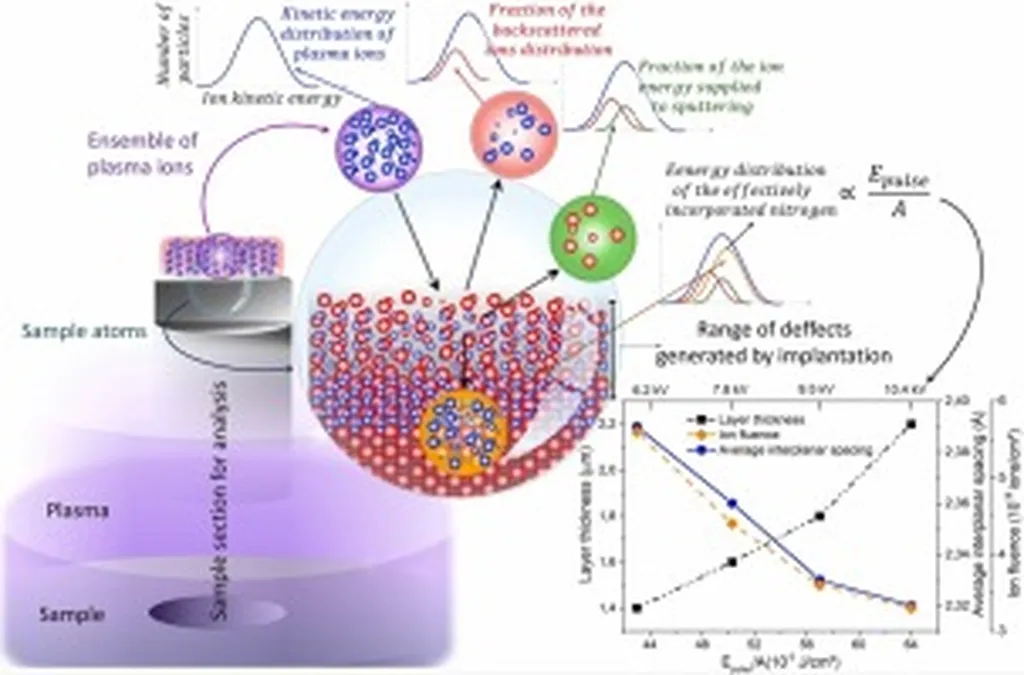

At the heart of this research is the low-temperature thermochemical treatment of face-centered cubic (FCC) alloys, a process that has garnered significant attention for its potential to revolutionize surface engineering. Francesca Borgioli, lead author of the study and a researcher at the Department of Industrial Engineering (DIEF) at the University of Florence, explains, “By treating these alloys at temperatures below 500°C in media rich in nitrogen and/or carbon, we can inhibit the formation of chromium compounds. This allows interstitial atoms to be retained in the FCC lattice beyond their solubility limit, creating a supersaturated solid solution known as expanded austenite or S-phase.”

The S-phase is renowned for its exceptional hardness and superior corrosion resistance, making it an ideal candidate for applications in harsh environments. Borgioli’s work highlights the transformative effects of this phase on various properties, including tribological performance, fatigue resistance, and biocompatibility. “The opportunities here are immense,” Borgioli notes. “This phase can be produced in a wide range of alloys, from traditional austenitic steels to the more recent high-entropy alloys, offering tailored solutions for specific industrial needs.”

The study delves into the role of alloy elements in promoting or hindering the formation of expanded austenite and the competing compound precipitates. By understanding these interactions, researchers can optimize treatment conditions to achieve desired properties. “The challenges are significant, but the potential rewards are even greater,” Borgioli adds. “We are just scratching the surface of what is possible with these treatments.”

For the energy sector, the implications are profound. Enhanced corrosion resistance and durability can lead to longer-lasting components, reduced maintenance costs, and improved safety. As Borgioli’s research suggests, the future of surface modification lies in the strategic application of low-temperature thermochemical treatments, paving the way for innovative solutions that can withstand the demanding conditions of energy production and transmission.

In the rapidly evolving landscape of materials science, this study serves as a beacon of progress, illuminating new paths for exploration and application. As Borgioli and her colleagues continue to push the boundaries of what is possible, the energy sector stands to benefit from these advancements, driving forward the development of more resilient and efficient technologies.