In the quest to enhance the durability and efficiency of lightweight alloys, a team of researchers led by Yuheng Zhen from Northeastern University in Shenyang, China, has made a significant stride. Their recent study, published in the journal *Corrosion Communications* (translated to English as “Anti-corrosion Communication”), focuses on developing an electrically conductive and corrosion-resistant coating for magnesium-lithium (Mg–Li) alloys. This breakthrough could have profound implications for the energy sector, particularly in applications where lightweight and corrosion resistance are paramount.

Mg–Li alloys are known for their exceptional strength-to-weight ratio, making them ideal for use in aerospace, automotive, and renewable energy technologies. However, their susceptibility to corrosion has been a longstanding challenge. “The development of a coating that can simultaneously provide electrical conductivity and corrosion resistance is a game-changer,” said Yuheng Zhen, lead author of the study. This innovation could extend the lifespan of components in harsh environments, reducing maintenance costs and improving overall system reliability.

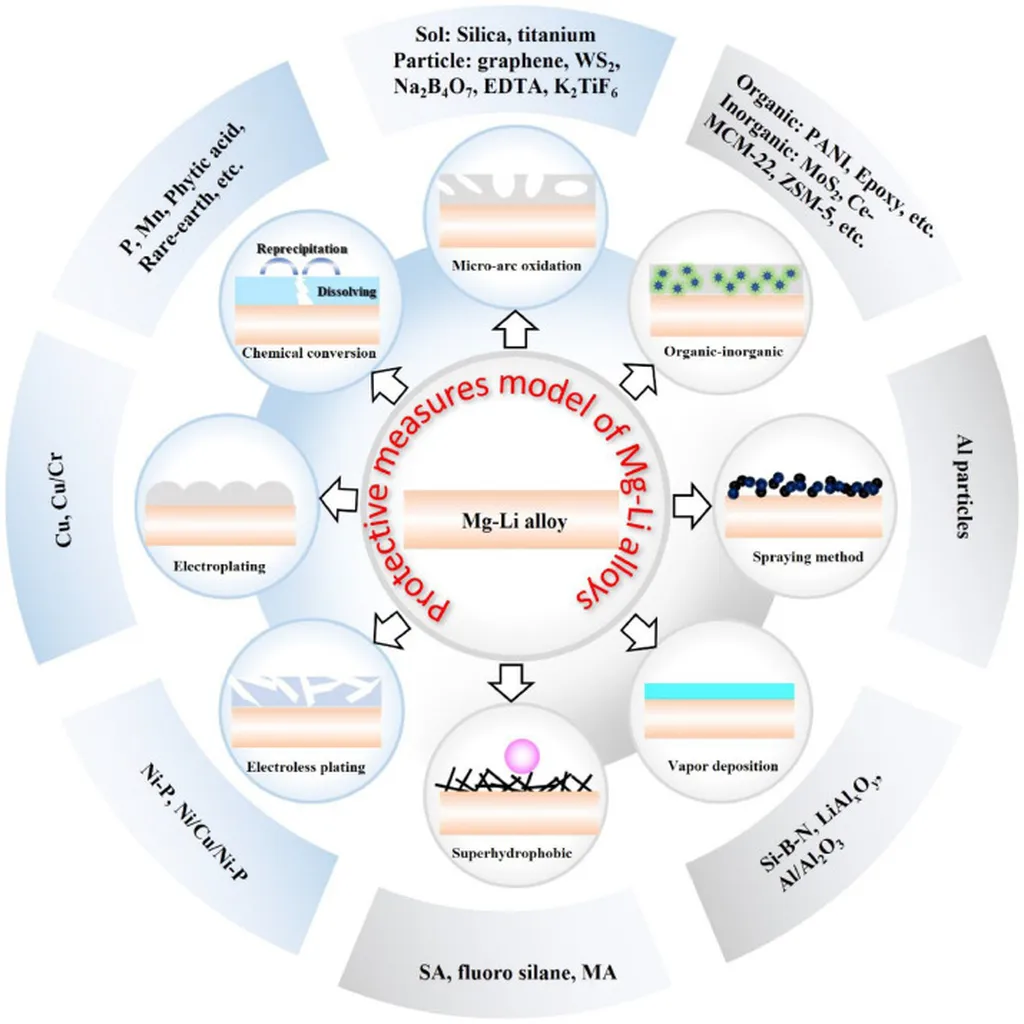

The research team’s approach involves a chemical conversion coating process, which transforms the surface of the alloy into a protective layer. This layer not only shields the underlying material from corrosive elements but also maintains electrical conductivity, a critical factor for many energy applications. “By addressing both corrosion and conductivity, we are opening up new possibilities for the use of Mg–Li alloys in high-performance and high-demand environments,” Zhen explained.

The implications for the energy sector are vast. In the aerospace industry, lighter materials can lead to more fuel-efficient aircraft, reducing carbon emissions and operational costs. In the automotive sector, the use of lightweight alloys can improve vehicle efficiency and performance. Additionally, in renewable energy technologies such as wind turbines and solar panels, corrosion-resistant materials can enhance durability and reduce the need for frequent replacements.

This research is not just a scientific achievement but a stepping stone towards more sustainable and efficient energy solutions. As Yuheng Zhen and his team continue to refine their coating technology, the potential for widespread adoption in various industries becomes increasingly promising. The study, published in *Corrosion Communications*, serves as a testament to the ongoing efforts to push the boundaries of materials science and engineering.

In the broader context, this research highlights the importance of interdisciplinary collaboration and innovation. By combining expertise in chemistry, materials science, and engineering, the team has developed a solution that addresses a critical challenge in the energy sector. As the world moves towards more sustainable and efficient energy solutions, such advancements will be crucial in shaping the future of technology and industry.