In the relentless pursuit of enhancing the durability of materials used in extreme environments, researchers have made a significant stride in understanding the oxidation behavior of GH4169 superalloy, a critical material in the energy sector. This breakthrough, published in the journal *Corrosion Communications* (translated from Chinese as *Corrosion Communications*), could potentially reshape how industries approach material degradation in high-temperature applications.

Dr. Lei Yin, from the College of Materials Science and Engineering at Taiyuan University of Technology in China, led the study that delves into the initial oxidation mechanisms of GH4169 superalloy at 1000 °C. The research focuses on the first 3600 seconds of oxidation, a crucial period that sets the stage for the material’s long-term performance. “Understanding the initial oxidation behavior is like reading the first chapter of a book,” Yin explains. “It gives us insights into how the story might unfold, allowing us to make informed decisions about the material’s future.”

The study reveals that the oxide layer formed on the superalloy consists of three distinct layers. The outer layer is composed of chromium and iron oxides, while the middle layer is a mixture of niobium and molybdenum oxides. The inner layer, closest to the metal surface, is enriched with aluminum and titanium oxides. This layered structure is not just a passive byproduct of oxidation but plays a significant role in the material’s resistance to further degradation.

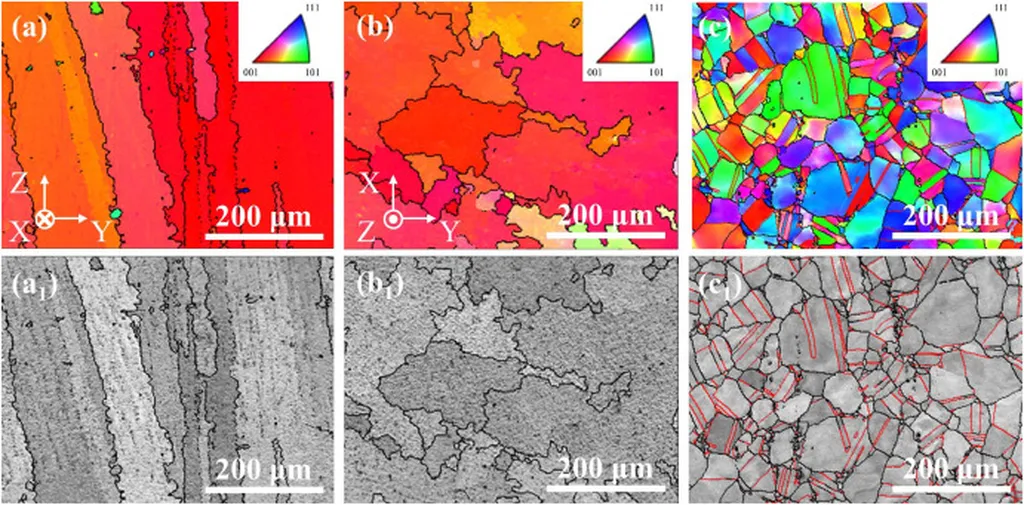

One of the most intriguing findings is that initial oxidation starts preferentially at grain boundaries, the interfaces between individual grains in the material’s microstructure. This observation underscores the importance of grain boundary engineering in enhancing the material’s oxidation resistance. “Grain boundaries are like the weak links in a chain,” Yin notes. “By strengthening these links, we can significantly improve the overall performance of the material.”

The study also highlights the role of precipitates, specifically γ′ and γ″ phases, in improving the oxidation resistance of GH4169 superalloy. These precipitates, tiny particles embedded within the material’s microstructure, act as barriers to the diffusion of oxygen and other reactive elements, thereby slowing down the oxidation process. “Precipitates are like tiny bodyguards,” Yin says. “They protect the material from the onslaught of oxidation, extending its lifespan.”

The implications of this research are far-reaching, particularly for the energy sector. GH4169 superalloy is widely used in high-temperature applications, such as gas turbines and aerospace engines, where oxidation resistance is paramount. By understanding and controlling the initial oxidation behavior of this material, industries can develop more durable and efficient components, leading to significant cost savings and performance improvements.

Moreover, the study provides a roadmap for future research in the field of material science. By focusing on the initial oxidation behavior and the role of precipitates, researchers can explore new strategies for enhancing the oxidation resistance of various materials. “This is just the beginning,” Yin concludes. “There’s still much to learn and discover. But every step forward brings us closer to our goal of creating materials that can withstand the harshest of environments.”

As industries continue to push the boundaries of performance and efficiency, the insights gained from this research will be invaluable. It’s a testament to the power of fundamental science in driving technological innovation and shaping the future of the energy sector.