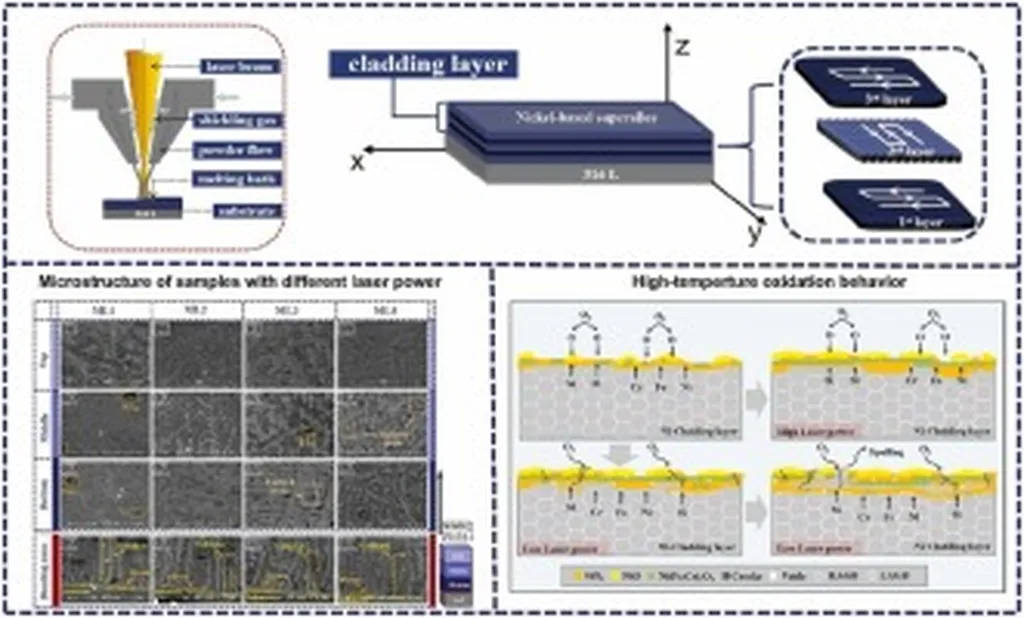

In a groundbreaking development that could reshape the energy sector, researchers have defied conventional wisdom to enhance the high-temperature performance of a widely used superalloy. Xiaopeng Cheng and his team at the State Key Laboratory of High Performance Roll Materials and Composite Forming, School of Materials Science and Engineering, Tianjin University, have successfully incorporated a high content of yttrium into Hastelloy X, a nickel-based superalloy, using laser powder bed fusion—a type of additive manufacturing. Their findings, published in the journal *Materials Research Letters* (translated as *Materials Research Letters*), could lead to more durable and efficient components for energy generation and other high-temperature applications.

The conventional approach to improving the creep performance of Hastelloy X has been to add low levels of yttrium. However, Cheng and his team took a different tack, incorporating a high content of yttrium (0.76 wt.%) into the alloy. This innovative approach led to the formation of uniformly dispersed nano-sized Ni5Y phases at the cell boundaries. The result? A sixfold increase in creep rupture lifetime and a lower minimum creep rate compared to standard Hastelloy X at 750°C.

“The Ni5Y phase promotes Cr23C6 nucleation, forming chain-like Ni5Y-Cr23C6-σ precipitates, which mitigate embrittlement at medium temperatures,” Cheng explained. This is a significant finding, as embrittlement has been a persistent challenge in the development of high-temperature alloys.

The research also revealed that dense hexagonal dislocation networks at the Ni5Y/matrix interfaces facilitate stress relaxation via cross-slip, preventing interfacial cracking. This mechanism could pave the way for the development of more resilient alloys for use in extreme environments.

The implications for the energy sector are substantial. The enhanced creep resistance and improved durability of the yttrium-enriched Hastelloy X could lead to more efficient and reliable components for power generation, particularly in gas turbines and other high-temperature applications. This could translate into significant cost savings and improved performance for energy providers.

Moreover, the use of additive manufacturing in this research highlights the potential of this technology to drive innovation in materials science. As Cheng noted, “This work demonstrates the potential of additive manufacturing to create novel alloys with enhanced properties.”

The research by Cheng and his team is a testament to the power of innovation and the potential of additive manufacturing to revolutionize the development of high-performance materials. As the energy sector continues to evolve, the need for durable, efficient, and reliable materials will only grow. This research offers a promising path forward, one that could shape the future of energy generation and other high-temperature applications.