In the quest to improve biodegradable orthopedic implants, researchers have turned to a promising strategy: alloying zinc (Zn) with magnesium (Mg) and refining the grain size to enhance mechanical properties and corrosion resistance. A recent study led by Yifan Wang from the Department of Orthopaedic Surgery at The Third People’s Hospital of Chengdu in China, published in the journal *Materials Research Express* (translated as “Materials Research Express”), sheds light on the potential of this approach.

The study focuses on the Zn-0.1 Mg alloy, which undergoes extrusion and rolling processes to achieve significant grain refinement. After extrusion, the alloy exhibits an average grain size of 8.17 micrometers, which further decreases to 0.71 micrometers after rolling. This refined microstructure not only bolsters the mechanical properties but also enhances corrosion resistance, making it a strong candidate for orthopedic applications.

“Grain boundary strengthening emerges as the predominant strengthening mechanism in the as-rolled Zn-0.1 Mg alloy with an ultrafine-grained microstructure,” explains Wang. This refinement process leads to a notable increase in strength and improved corrosion resistance, primarily due to the higher grain boundary density, which facilitates the formation of a protective corrosion layer.

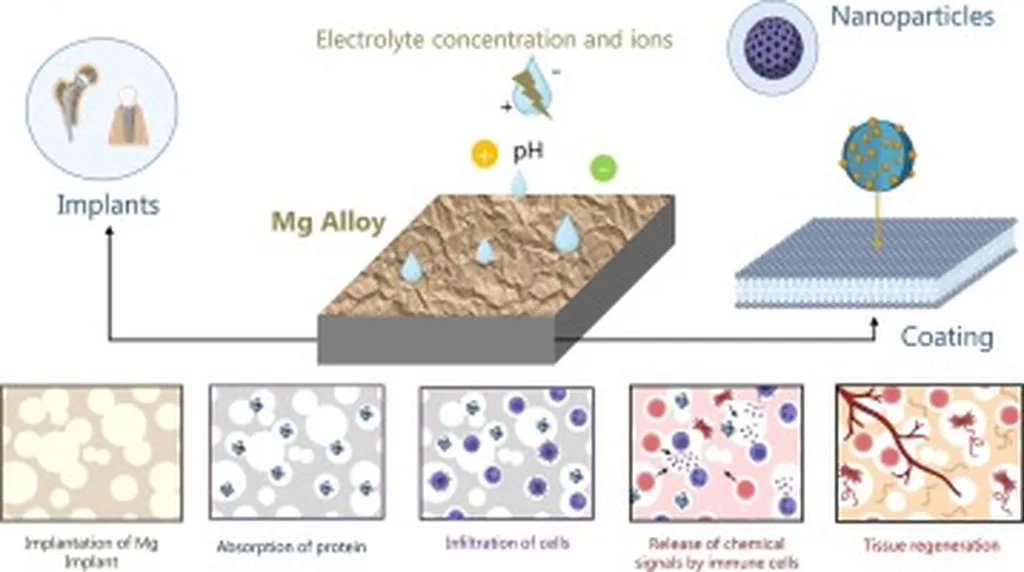

The study also highlights the biocompatibility of Zn-0.1 Mg alloys, which exhibit comparable cytocompatibility, osteogenic potential, and antibacterial properties. These findings provide an effective approach to enhancing the mechanical properties of diluted Zn-Mg alloys by refining their grain size to the sub-micrometer scale.

The implications of this research are significant for the medical device industry, particularly in the development of biodegradable orthopedic implants. By refining the grain size of Zn-Mg alloys, manufacturers can produce implants with superior mechanical properties and enhanced corrosion resistance, ultimately improving patient outcomes.

As Wang notes, “Our findings offer a promising avenue for the development of next-generation orthopedic implants that are not only strong and durable but also biocompatible and resistant to corrosion.” This research could pave the way for innovative solutions in the field of orthopedics, addressing the critical need for implants that can withstand the demanding conditions of the human body while promoting healing and reducing the risk of complications.

In the broader context, the study published in *Materials Research Express* underscores the importance of advanced materials science in driving technological advancements in the medical field. As researchers continue to explore the potential of Zn-Mg alloys, the future of orthopedic implants looks increasingly promising, with the potential to revolutionize patient care and improve quality of life for those in need of surgical interventions.