In a groundbreaking development poised to revolutionize the prosthetic industry, researchers have turned to nature for inspiration, creating a 3D-printed pylon for lower-limb prosthetic devices that is not only lighter but also more cost-effective than traditional metal counterparts. This innovative design, inspired by the architecture of the Euplectella aspergillum sponge, could significantly enhance accessibility to prosthetic technology, particularly in resource-limited settings.

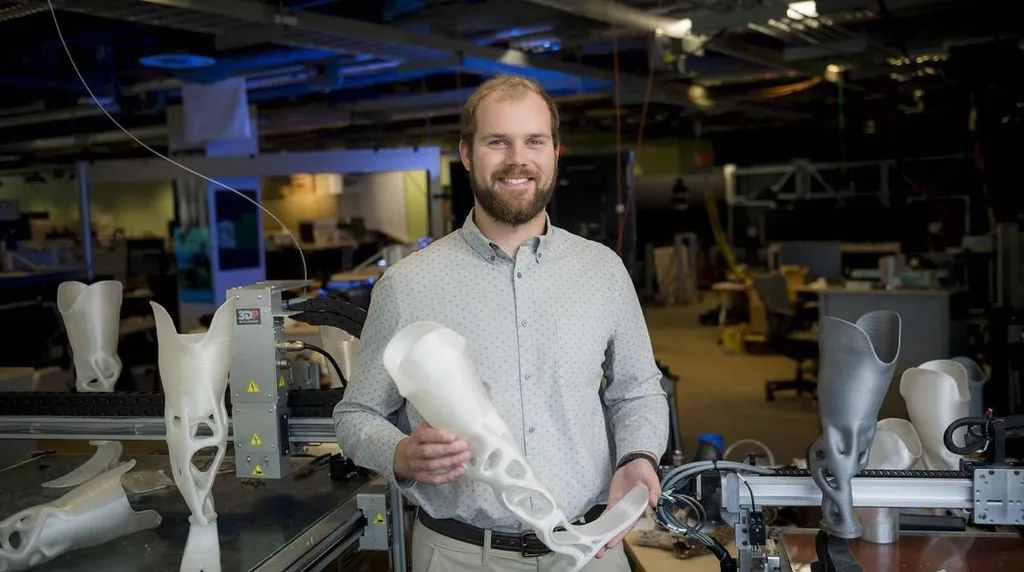

At the heart of this research is Fariborz Tavangarian, a mechanical engineering expert from the Pennsylvania State University. Tavangarian and his team have successfully demonstrated that a polylactic acid (PLA) prosthetic pylon, fabricated using additive manufacturing techniques, can meet stringent international mechanical standards. “We aimed to create a pylon that could withstand the rigorous demands of daily use while being significantly lighter and more affordable,” Tavangarian explained. “By drawing inspiration from nature, we were able to design a structure that is both robust and efficient.”

The study, published in the journal *Exploration of BioMat-X* (translated to *Exploration of Biomaterials-X*), details how the team employed a biomimetic lattice shell to envelop a cylindrical core, mimicking the sponge’s natural architecture to enhance structural integrity. The resulting pylon not only passed all ISO 10328 mechanical tests but also exhibited impressive performance metrics. It sustained a maximum static compression load of 7,901 N, far exceeding the ISO target of 4,480 N, and completed over 3 million cycles under dynamic loading without failure. Moreover, the 3D-printed units weighed approximately 30% less than comparable metal pylons, offering a significant reduction in patient burden.

The implications of this research extend beyond the prosthetic industry. The use of additive manufacturing and biomimetic design principles could pave the way for innovative solutions in various sectors, including construction and energy. “This technology has the potential to transform how we approach material design and manufacturing,” Tavangarian noted. “By leveraging nature’s time-tested structures, we can create materials that are not only stronger and lighter but also more sustainable and cost-effective.”

As the world continues to grapple with the challenges of accessibility and sustainability, this research offers a glimmer of hope. The successful development of a lightweight, cost-effective prosthetic pylon could serve as a catalyst for further advancements in the field, ultimately improving the quality of life for millions of individuals worldwide. With ongoing in-vitro and in-vivo validation, the future of prosthetic technology looks brighter than ever.