In the rapidly evolving world of wearable electronics, a groundbreaking approach is emerging that could revolutionize how we integrate technology into our daily lives. Researchers, led by Bekinew Kitaw Dejene from the Department of Textile Engineering at Hawassa University in Ethiopia, are exploring the potential of inkjet printing conductive nanomaterials onto textiles. This method promises to merge the precision of digital fabrication with the comfort and flexibility of traditional textiles, opening up new avenues for innovation in wearable technology.

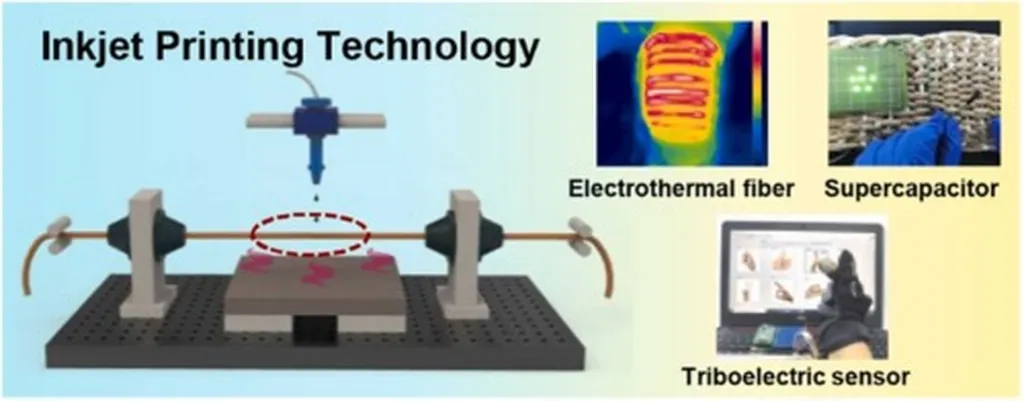

The study, published in *Materials Today Advances* (which translates to *Advances in Materials Today*), delves into the latest advancements in material formulations, printing methodologies, and functional applications. Dejene and his team have critically examined the interplay between nanomaterial properties—such as metallic nanoparticles, carbon-based materials, and conductive polymers—and printing parameters. Their goal is to achieve high-resolution, durable, and conductive patterns on a variety of textile substrates.

One of the most compelling aspects of this research is its potential impact on the energy sector. Wearable electronics that can monitor physiological data, generate flexible energy systems, and create advanced human-machine interfaces could transform how we interact with energy technologies. Imagine clothing that not only monitors your health but also harvests energy from your movements or the environment. This could lead to more sustainable and efficient energy solutions, particularly in wearable and portable devices.

“Wearable electronics are no longer a futuristic concept; they are becoming a reality,” says Dejene. “By leveraging inkjet printing of conductive nanomaterials, we can create textiles that are not only functional but also comfortable and durable. This could revolutionize industries ranging from healthcare to energy.”

However, the journey to commercialization is not without its challenges. The research highlights persistent issues such as material stability, interfacial adhesion, wash durability, and large-scale manufacturing constraints. To address these, the team has proposed innovative solutions, including self-healing composites, hybrid printing techniques, and environmentally benign conductive inks. These advancements could pave the way for more robust and sustainable wearable technologies.

Looking ahead, the study explores emerging trends in intelligent textiles, such as AI-enabled fabrication and bio-integrated devices. These trends are poised to drive future developments in the field, making wearable electronics more intelligent, adaptable, and integrated into our daily lives.

As Dejene notes, “The future of wearable electronics lies in our ability to overcome these challenges and create technologies that are not only innovative but also practical and sustainable.” The research underscores the need for standardized testing protocols, sustainable material lifecycles, and cross-disciplinary collaboration to bridge the gap between laboratory innovations and mass production.

In conclusion, the work of Dejene and his team represents a significant step forward in the field of wearable electronics. By addressing the challenges and leveraging the latest advancements in materials and printing technologies, they are paving the way for a future where wearable electronics are not just a novelty but a practical and integral part of our lives. The implications for the energy sector are particularly exciting, offering new possibilities for sustainable and efficient energy solutions. As the field continues to evolve, the insights from this research will be invaluable in shaping the future of wearable technology.