In the heart of China’s industrial landscape, a novel approach to waste management and sustainable construction is emerging, promising to turn two of the country’s most abundant solid wastes into valuable resources. Researchers, led by Guofu Chen from the College of Materials Science and Engineering at Xi’an University of Architecture & Technology, have pioneered a method to transform coal gangue (CG) and waste incineration fly ash (WIFA) into high-performance cementitious materials through high-temperature sintering.

The study, published in the journal *Developments in the Built Environment* (translated as “Advances in Construction and Urban Renewal”), demonstrates how these waste materials can be repurposed, addressing both environmental concerns and industrial demands. “The utilization of CG and WIFA in cement-based materials not only reduces the environmental impact but also enhances the mechanical properties of the final product,” Chen explains.

China produces vast amounts of coal gangue as a byproduct of coal mining and waste incineration fly ash from municipal solid waste incineration. Both materials pose significant disposal challenges and environmental risks. Chen’s research offers a dual solution: valorizing these wastes and mitigating their potential harm.

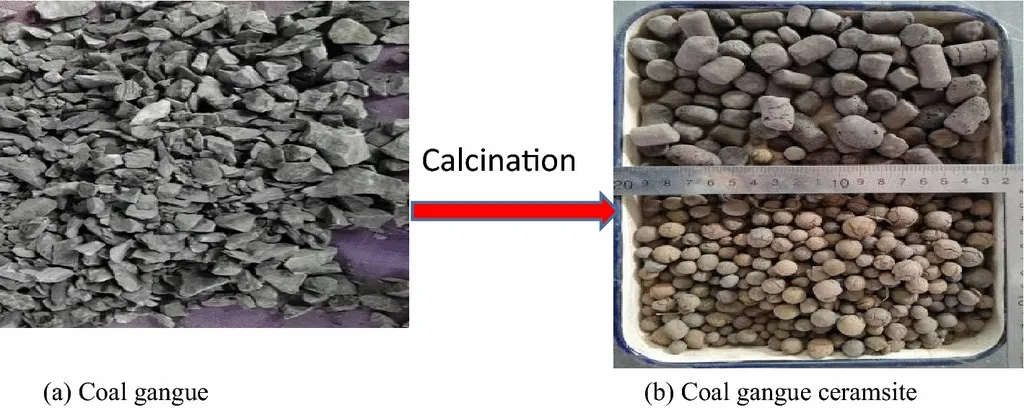

The process involves calcining CG and WIFA at varying temperatures and blending them to create CG-WIFA, a substitute for traditional cement. The team found that calcining above 1000°C significantly improved the roundness of the particles, enhancing the flowability of the mortar. Notably, the blend labeled 1200CG-20WIFA achieved a slump of 225 mm, a 10.8% increase compared to the control sample.

The pozzolanic activity—a measure of the material’s ability to react with calcium hydroxide and water to form compounds with cementitious properties—was also substantially improved. “Upon compounding with 20% WIFA, the pozzolanic activities of 700CG-0WIFA and 800CG-0WIFA increased to 88.3% and 80.2%, respectively,” Chen notes. This enhancement suggests that the addition of WIFA accelerates the hydration reaction of key cement components, C3S and C2S, and refines the pore structure of the cement, leading to stronger and more durable materials.

The implications for the energy and construction sectors are profound. By converting waste into high-value construction materials, industries can reduce disposal costs and carbon footprints while meeting growing demands for sustainable building solutions. “This research opens up new avenues for the circular economy in the construction industry,” Chen adds. “It’s a win-win for both the environment and the economy.”

As the world grapples with the challenges of waste management and sustainable development, Chen’s work offers a beacon of hope. By turning waste into wealth, this innovative approach could reshape the future of construction, energy, and environmental stewardship.