In the quest for lighter, stronger materials, the construction and energy sectors have increasingly turned to unidirectional fiber-reinforced thermoplastic (UD) tapes. These tapes, used for local reinforcement of plastic parts, are a critical component in the push towards more efficient, lightweight structures. However, a persistent challenge in their manufacturing process has been the inconsistent spreading of fiber rovings, particularly for heavy tows like carbon-fiber rovings with more than 24K filaments. This inconsistency can lead to defects in the final reinforced components, undermining their performance and reliability.

Enter Stefan Kohl, a researcher at the Institute of Polymer Processing and Digital Transformation at Johannes Kepler University Linz, Austria. Kohl and his team have proposed a novel solution to this longstanding problem: a spreading technique based on the principle of forced conveying. This method aims to provide constant final widths of fiber rovings, largely independent of the input roving quality.

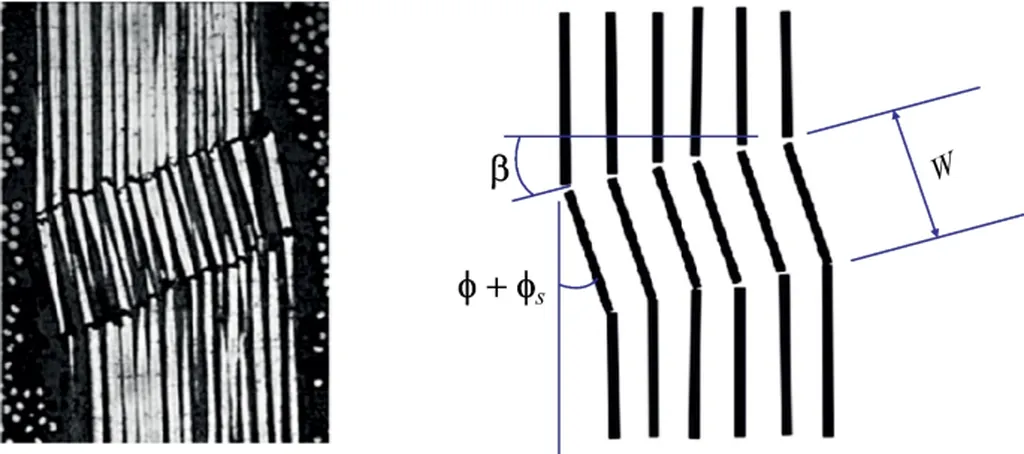

In a feasibility study published in the Journal of Engineered Fibers and Fabrics (translated as “Journal of Engineered Fibers and Textiles”), Kohl and his colleagues investigated the spreading behavior of a 60K carbon fiber roving using their new technique. The results were promising. The forced conveying method provided constant final widths, regardless of the initial width and cross-sectional shape of the roving. Statistical analysis further revealed that both the wrap angle and the circumferential speed of the roller, along with their quadratic influences, had highly significant effects on the final spread width.

“The variability in the input roving quality has been a major hurdle in achieving consistent spread widths,” Kohl explained. “Our method aims to mitigate this issue, ensuring a more uniform spread that is crucial for homogeneous impregnation and, ultimately, defect-free components.”

The implications of this research are significant, particularly for the energy sector. Lightweight, high-strength materials are in high demand for applications such as wind turbine blades, where weight reduction can lead to increased energy efficiency. The ability to produce consistent, high-quality UD tapes could accelerate the adoption of these materials in various energy-related applications.

Moreover, the predictive accuracy of the quadratic model developed by Kohl’s team, with an R² value of 0.9972, suggests that the method could be fine-tuned for specific applications, further enhancing its commercial potential.

As the energy sector continues to seek innovative solutions for more efficient and sustainable technologies, advancements in material science like Kohl’s forced conveying technique could play a pivotal role. By addressing a critical step in the manufacturing process, this research not only shapes the future of lightweight construction but also contributes to the broader goals of energy efficiency and sustainability.

In the words of Kohl, “This is just the beginning. The potential applications of our method are vast, and we are excited to explore them further.”