In the quest for more efficient and sustainable manufacturing processes, researchers are continually exploring innovative techniques to improve the strength and reliability of metal joints. A recent study published in the journal *Frontiers in Materials and Technologies* (translated from Russian) sheds light on a promising advancement in ultrasonic welding of metals, particularly copper, which could have significant implications for the energy sector.

Elvina R. Shayakhmetova, a researcher at the Institute for Metals Superplasticity Problems of the Russian Academy of Sciences in Ufa, led a study investigating the strength of joints produced by ultrasonic spot welding of copper plates using tools with different tooth heights. The research focuses on enhancing the strength characteristics of solid-state joints, which are crucial for various industrial applications, including those in the energy sector.

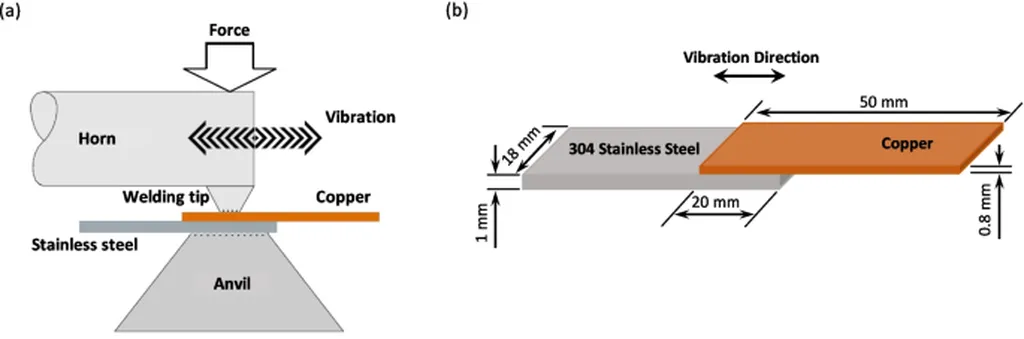

Ultrasonic welding of metals is an energy-efficient and environmentally friendly technology that allows for the creation of solid-state joints between thin metal blanks. However, the widespread adoption of this technology has been hindered by the low strength and instability of the resulting joints. To address this challenge, Shayakhmetova and her team explored the use of welding tools with different tooth heights to improve the transmission of ultrasonic vibration energy to the joint zone.

“The key to improving the strength of ultrasonic welds lies in the design of the welding tool,” Shayakhmetova explained. “By optimizing the tooth height on the tool’s surface, we can significantly enhance the stability and strength of the joints.”

The study involved ultrasonic welding of copper plates using tools with tooth heights of 0.1 mm and 0.4 mm. The welding process was conducted at a frequency of 20 kHz and a vibration amplitude of 18–20 μm, with welding durations of 2 and 3 seconds, and a clamping force of 2.5 kN. The researchers then analyzed the fracture load, fracture energy, and distribution of normal strains in the weld spot, as well as the stress intensity factors in its vicinity.

The findings revealed that after ultrasonic welding for 3 seconds, the strength characteristics of the joints produced with different tools reached their highest values. Notably, the joints produced with the smaller teeth (0.1 mm) exhibited half the experimental data scatter compared to those produced with larger teeth (0.4 mm). This indicates a more consistent and reliable welding process when using tools with smaller teeth.

“Our results demonstrate that the choice of tool design can significantly impact the quality and reliability of ultrasonic welds,” Shayakhmetova noted. “This research provides valuable insights into optimizing the welding process for improved performance and consistency.”

The study also highlighted the different fracture behaviors of the joints. Joints produced with the smaller teeth fractured along the interface of the joint, while those produced with the larger teeth exhibited nugget pull-out, which is attributed to an increase in the stress intensity factor at the tip of the concentrator surrounding the weld spot.

The implications of this research are far-reaching, particularly for the energy sector, where the demand for reliable and efficient metal joints is high. As the world transitions towards renewable energy sources, the need for robust and sustainable manufacturing processes becomes increasingly critical. The findings of this study could pave the way for advancements in the production of solar panels, wind turbines, and other energy-related components, ultimately contributing to a more sustainable future.

“By improving the strength and reliability of ultrasonic welds, we can enhance the performance and longevity of energy-related components,” Shayakhmetova said. “This research is a step towards more efficient and sustainable manufacturing processes in the energy sector.”

As the field of ultrasonic welding continues to evolve, the insights gained from this study could shape future developments, leading to more advanced and reliable welding techniques. The research published in *Frontiers in Materials and Technologies* not only advances our understanding of ultrasonic welding but also highlights the importance of innovative tool design in achieving superior joint strength and consistency.