In the world of precision engineering, the humble razor blade is a testament to the intricate dance between material science and cutting-edge technology. A recent study, published in the journal “Akademie Materiálové Vědy” (Academia Materials Science), has peeled back the layers of this everyday tool, revealing insights that could resonate far beyond the bathroom mirror, potentially influencing industries where precision cutting is paramount, including the energy sector.

Miroslav Piska, lead author of the study and a researcher at the Tool Factories Association Czech Republic in Brno, and his team set out to dissect the cutting performance of steel razor blades. Their findings, while seemingly mundane at first glance, offer a profound look into the mechanics of cutting and wear, with implications for industries that rely on similar principles.

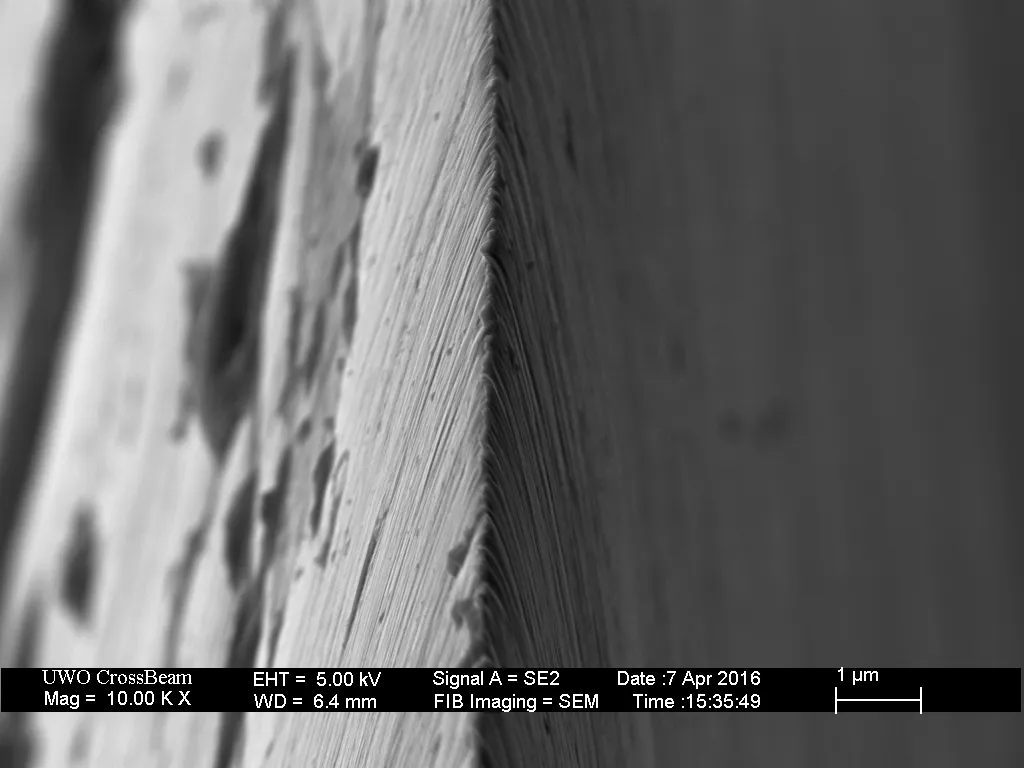

The team tested five types of shaving blades from respected world producers, examining the quality of material, cutting microgeometry, and surface roughness. They found that the best-performing blades boasted a double-wedge design with specific top angles, a keen edge radius, and an exceptionally smooth surface. The superior material contained a high percentage of chromium and was hardened to a remarkable degree.

“The wear mechanism began with the yielding of the cutting-edge asperities, then continued with the production of the bent hooked cutting edges, causing loss of stability, and finally ended with the total collapse and destruction of the cutting blade,” Piska explained. This understanding of wear and tear could be pivotal in developing more durable cutting tools for various industries.

The study also confirmed a good correlation between the price and the quality of the razors, a finding that could guide consumers and manufacturers alike. But the implications stretch beyond personal grooming. In the energy sector, for instance, precision cutting is crucial in the manufacturing and maintenance of components. Understanding the factors that contribute to a blade’s longevity and performance could lead to innovations in tool design and material composition, ultimately reducing costs and improving efficiency.

Piska’s research underscores the importance of fundamental studies in driving technological advancements. As we stand on the brink of a new era in manufacturing and energy production, the lessons learned from something as simple as a razor blade could illuminate the path forward. The study, published in “Akademie Materiálové Vědy,” serves as a reminder that even the most ordinary objects can hold extraordinary insights, waiting to be uncovered by the curious and the diligent.