In the rapidly evolving world of advanced manufacturing, a groundbreaking study led by Dekun Kong from Jilin University’s Key Laboratory of Bionic Engineering is set to redefine the capabilities of ceramic materials. Published in the *International Journal of Extreme Manufacturing* (which translates to *International Journal of Extreme Manufacturing* in English), this research introduces a novel ceramic precursor system that combines phase-separating hydrogels and shape memory polymers, opening new avenues for intelligent manufacturing and multifunctional device development.

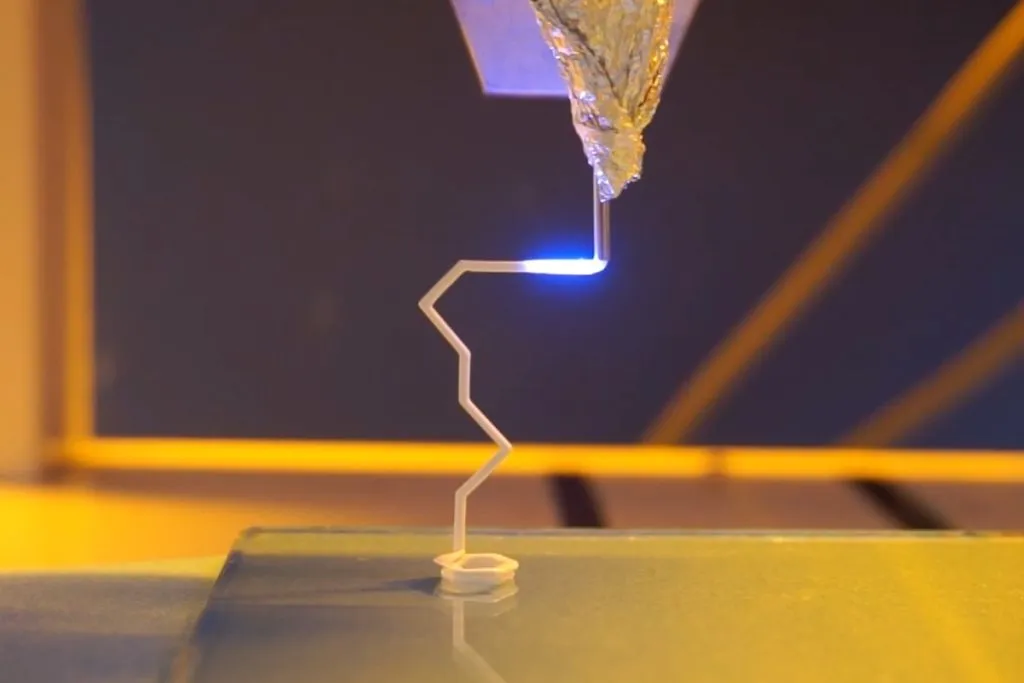

The study addresses critical limitations in current ceramic 4D printing technologies, particularly in responsiveness, reversibility, and mechanical performance. By integrating a nano-ceramic particle enhancement strategy with stereolithography 3D printing, the researchers achieved high-precision fabrication of complex structures. “Our approach enables precise control over the recovery onset time, which is a significant advancement in the field of smart materials,” said Kong.

The synergistic effect of hydrogels and shape memory polymers allows for programmable recovery onset and reversible deformation, making these materials highly adaptable for various applications. The researchers demonstrated that by adjusting precursor composition, programming time, and structural thickness, they could manipulate the phase-separation kinetics-driven delayed recovery mechanism. This level of control is pivotal for developing intelligent manufacturing processes and on-demand shaping of complex structures.

One of the most compelling aspects of this research is its potential impact on the energy sector. The ability to create materials with environmentally responsive dynamic deformation capabilities can lead to the development of more efficient and adaptable energy systems. For instance, these materials could be used in the creation of smart grids, where components can autonomously adjust to changing environmental conditions, enhancing overall system efficiency and reliability.

Moreover, the study explores the thermal response mechanisms of the precursor materials and their potential for multi-shape transformation in biomedical applications. This versatility extends the applicability of these materials beyond the energy sector, into fields such as healthcare and robotics. “The autonomous reversible deformation of ceramic precursors opens up new possibilities for specific applications, particularly in areas requiring high precision and adaptability,” Kong added.

The implications of this research are far-reaching. As the energy sector continues to evolve, the demand for smart materials that can adapt to dynamic environments will only grow. The programmable ceramic precursor system developed by Kong and his team represents a significant step forward in meeting this demand. By enabling precise control over material properties, this technology can facilitate the development of more efficient and sustainable energy solutions.

In conclusion, the research led by Dekun Kong at Jilin University’s Key Laboratory of Bionic Engineering marks a significant milestone in the field of smart materials and advanced manufacturing. Published in the *International Journal of Extreme Manufacturing*, this study not only addresses current limitations in ceramic 4D printing but also paves the way for innovative applications in the energy sector and beyond. As the world continues to seek more adaptable and efficient materials, the programmable ceramic precursor system offers a promising solution, shaping the future of intelligent manufacturing and multifunctional device development.