In the quest to develop stronger, more ductile steels for the energy sector, researchers have made a significant stride by unraveling the intricate relationship between processing, microstructure, and mechanical properties in medium manganese (Mn) steels. This breakthrough, led by J.L. Hernández-Rivera, could potentially reshape the landscape of steel manufacturing and energy infrastructure.

Medium Mn steels have long been touted for their exceptional combination of strength and ductility, but the precise processing conditions required to achieve these properties have remained elusive. Hernández-Rivera and his team set out to change that, focusing on the role of intercritical annealing—a heat treatment process that occurs between the ferrite and austenite phase transformation temperatures.

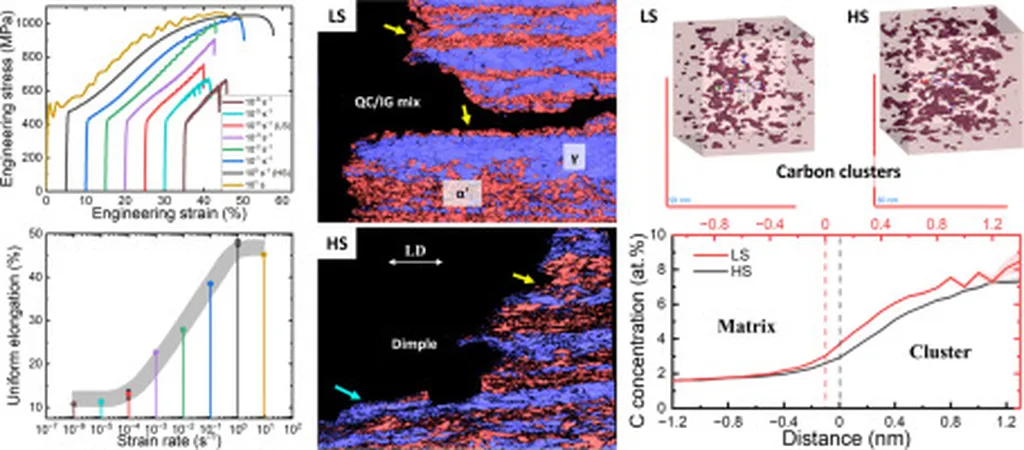

The researchers subjected a 7 wt.% Mn steel to controlled hot-rolling and intercritical annealing at two different temperatures: 700°C and 780°C. The results were revealing. “We found that annealing at 700°C produced the optimal balance of strength and ductility,” Hernández-Rivera explained. “Samples annealed at this temperature exhibited ultimate tensile strength and elongation, while those treated at 780°C showed brittle behavior with low elongation.”

The study, published in *Materials Research* (translated to English as “Materials Research”), also shed light on the role of NbC precipitates in the steel’s microstructure. These precipitates, identified after electrochemical extraction, played a crucial role in the steel’s mechanical properties.

The implications of this research for the energy sector are substantial. Stronger, more ductile steels could lead to more efficient and reliable energy infrastructure, from pipelines to power plants. “Understanding the precise processing conditions required to achieve superior mechanical properties is a significant step forward,” Hernández-Rivera noted. “This knowledge could pave the way for the development of new, high-performance steels tailored to the specific needs of the energy sector.”

As the energy sector continues to evolve, the demand for advanced materials that can withstand extreme conditions and provide reliable performance is only expected to grow. This research not only advances our understanding of medium Mn steels but also opens up new possibilities for innovation in the field of materials science and engineering. The findings could shape future developments, driving the creation of next-generation steels that are stronger, more ductile, and better suited to the demanding requirements of the energy sector.