In the world of bearing steels, where precision and performance are paramount, a recent study published in *Teshugang* (which translates to *Iron and Steel*) has shed new light on how hot rolling processes can significantly influence the microstructure of GCr15 bearing steel. This research, led by Liu Jing, offers valuable insights that could reshape manufacturing processes and enhance product quality in the energy sector.

GCr15 bearing steel is a critical material used in various high-stress applications, including turbines and heavy machinery. The study focused on the recrystallization behavior of this steel during hot rolling, a process that involves deforming the metal at high temperatures to refine its grain structure. By controlling this process, manufacturers can achieve finer grains, which in turn improves the steel’s mechanical properties.

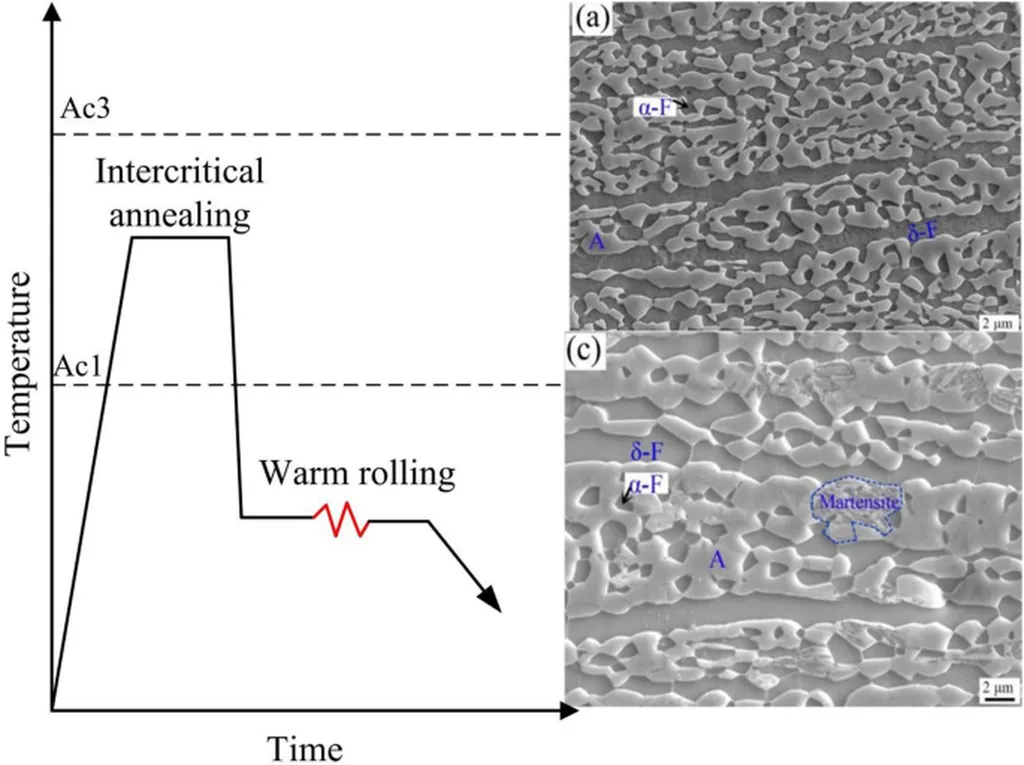

Liu Jing and the research team conducted simulations using a Gleeble 1500 thermal simulation machine to mimic the hot rolling process. They subjected samples of GCr15 bearing steel to multiple passes at temperatures ranging from 1,150 to 910 degrees Celsius. The results were promising: with an accumulated deformation of 82%, the grain size rating of the samples was 6, and the recrystallization ratio reached 91%.

“This level of control over the grain structure is crucial for enhancing the steel’s performance,” Liu Jing explained. “By fine-tuning the rolling parameters, we can achieve a more uniform and refined grain structure, which directly impacts the steel’s strength and durability.”

The study also revealed that increasing the percent reduction in the rolling process from 52% to 60% further refined the grain structure of the steel. This finding has significant implications for manufacturers, as it provides a clear pathway to optimizing the hot rolling process to achieve superior material properties.

For the energy sector, where bearing steels are subjected to extreme conditions, these advancements could lead to more reliable and long-lasting components. “The ability to control the grain structure at such a precise level opens up new possibilities for improving the performance of bearings in high-stress environments,” said a representative from a leading energy equipment manufacturer.

As the industry continues to push the boundaries of material science, this research highlights the importance of understanding and controlling the fundamental processes that govern material behavior. By leveraging these insights, manufacturers can develop more robust and efficient products, ultimately driving progress in the energy sector and beyond.

The study, published in *Teshugang*, serves as a testament to the ongoing advancements in metallurgical research and its potential to revolutionize industrial practices. As the energy sector continues to evolve, the insights gained from this research will undoubtedly play a pivotal role in shaping the future of bearing steel technology.