In the quest to enhance the performance of high carbon steel, a recent study published in *Teshugang*—translated from Chinese as “Iron and Steel”—has unveiled intriguing insights into the effects of microalloying with niobium (Nb) and vanadium (V) on the hot workability of these steels. The research, led by Liu Ping, offers promising implications for the energy sector, where high carbon steels are crucial for various applications, including pipelines and power generation equipment.

High carbon steels are prized for their strength and durability, but their workability at high temperatures can be challenging. The study aimed to understand how the addition of small amounts of Nb and V affects the steel’s behavior during hot working processes. Using a Cleeble 1500D thermal simulation machine, the researchers tested the reduction of area and tensile strength of specimens drilled and turned from cast billets of high carbon steel microalloyed with different combinations of Nb and V.

The results were revealing. “The hot plasticity of V-steel in the first brittle zone, around 1200°C, and the third brittle zone, between 1000°C and 800°C, was significantly better than that of Nb-steel and Nb-V steel,” Liu Ping explained. This improved workability could translate to more efficient and cost-effective manufacturing processes in industries that rely heavily on high carbon steels.

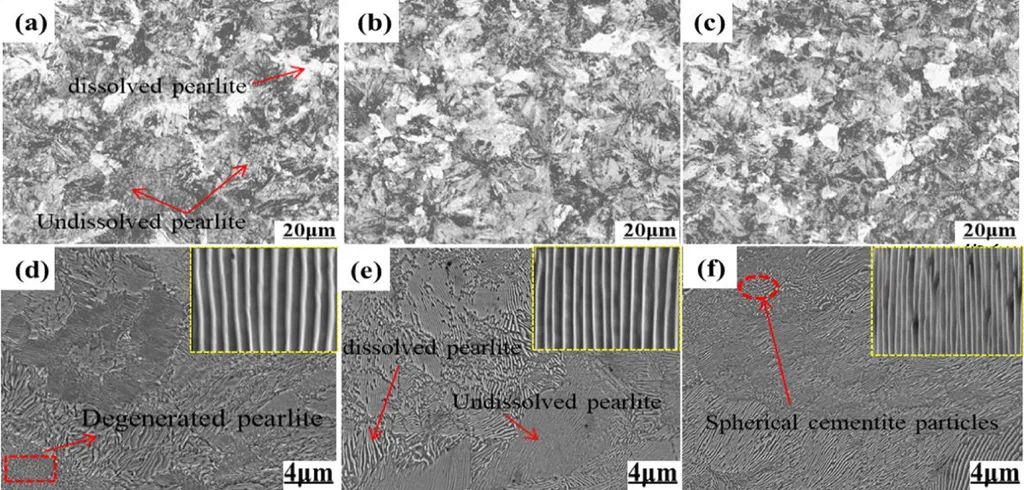

Scanning electron microscopy and energy spectrum analysis provided further clarity. The researchers found that Fe-Nb-C eutectic existed in the cast billet of Nb-steel, while Fe-Nb eutectic was present in the cast billet of Nb-V steel. These findings suggest that the type and amount of microalloying elements can significantly influence the microstructure and, consequently, the mechanical properties of the steel.

The commercial impacts of this research are substantial. In the energy sector, where high carbon steels are used in critical components, improving hot workability can lead to better performance and longer service life. This could result in reduced maintenance costs and increased operational efficiency, ultimately benefiting both manufacturers and end-users.

As the energy sector continues to evolve, the demand for high-performance materials is on the rise. The insights from Liu Ping’s research could shape future developments in the field, guiding manufacturers to optimize their alloy compositions for better performance and durability. The study, published in *Teshugang*, serves as a valuable resource for professionals seeking to push the boundaries of material science and engineering.

In an industry where every improvement counts, this research offers a glimpse into the future of high carbon steel manufacturing, promising advancements that could redefine the standards of performance and efficiency.